European

Nuclear Society

e-news

Issue 21 Summer 2008

http://www.euronuclear.org/e-news/e-news-21/concept-of-the-future.htm

Some four hundred Boiling Water Reactors (BWR) and Pressurized Water Reactors (PWR) have been in operation for several decades. The present concept, the High Pressure Boiling Water Reactor (HP-BWR) makes use of the operating experiences. HP-BWR combines the advantages and leaves out the disadvantages of the traditional BWRs and PWRs by taking in consideration the experiences gained during their operation. The best parts of the two traditional reactor types are used and the troublesome components are left out. The HP-BWR major benefits are;

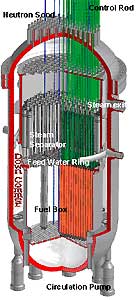

1. Safety is improved; -Gravity operated control rods -Large space for the cross formed control rods between fuel boxes -Bottom of the reactor vessel without numerous control rod penetrations -All the pipe connections to the reactor vessel are well above the top of the reactor core -Core spray is not needed -Internal circulation pumps to assure hydrodynamic stability.

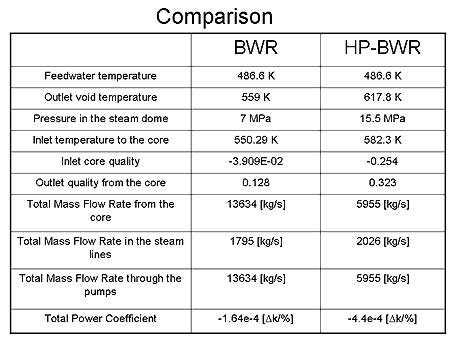

2. Environment friendly; -Improved thermal efficiency, feeding the turbine with ~340 0C (15 MPa) steam instead of ~285 0C (7MPa) -Less warm water release to the recipient and less uranium consumption per produced kWh

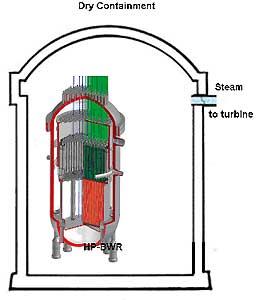

3. Cost effective, simple; -Direct cycle, no need for complicated steam generators -Moisture separators and steam dryers are inside the vessel and secondary separators and dryers can be installed outside the reactor vessel, inside or outside the containment -Simple dry containment

Now the time has come to move a step further and develop an improved type of power reactors. Common sense, public confidence and economic considerations demand that this new design should not be a big leap from the presently functioning machines, however it should be a significant improvement. Therefore it is important to avoid those parts of the older designs which caused trouble in the past e.g. PWR steam generators, BWR perforated reactor vessel bottoms and instead rely only on a stable construction with proven components which served well in the past. The High Pressure – Boiling Water Reactor (HP-BWR) attains these goals, by using the PWR; pressure vessel, the electro-magnetic control rod operator and the BWR; core internals, circulation pumps and steam and moisture separators.

Figure 1. The High Pressure Boiling Water Reactor

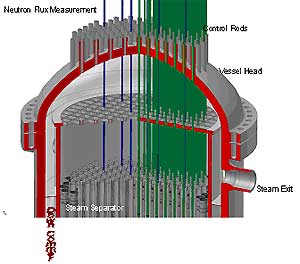

The control rods are gravity operated as this system served well in PWRs. However here the form is like a cross, as it is in the BWRs. This assures large space for the cross formed rods between the BWR type fuel boxes.

Figure 2. Reactor vessel head and reactor internals

The bottom of the reactor vessel now is without numerous control rod penetrations a great advantage compared with the previous design

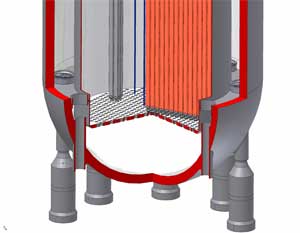

Figure 3. The bottom of the reactor vessel and circulation pumps

All the pipe connections to the reactor vessel are well above the top of the reactor core. This means that a pipe break would not empty the reactor vessel. Therefore core spray is not needed.

Internal circulation pumps are used to assure hydrodynamic stability. This way the orifices at the fuel channel inlets are chosen so that the one phase pressure drop will dominate over the two phase pressure drop to avoid hydrodynamic oscillations. By applying natural circulation one could omit the circulation pumps, however the margin to avoid hydrodynamic oscillations would be diminished.

Compared with the traditional BWR the HP-BWR has further advantages;

Table 1. Comparison between BWR and HP-BWR

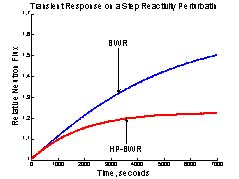

due to the high temperature, improved thermal efficiency and due to the increased negative power reactivity coefficient further improved inherent stability.

Figure 4. Long term stability without the use of any control system.

Inherently stable reactor

Improved thermal efficiency is assured by feeding the turbine with ~340°C (15.5MPa) steam instead of ~285°C (7MPa). The Carnot cycle theoretical efficiency (THot - TCold )/ THot is for BWR ~46% and for HP-BWR ~51% at TCold = 300 K. This demonstrate the advantage of the HP-BWR which utilizes the fuel more efficiently and releases less warm cooling water to the environment per produced kWh

The HP-BWR operates in direct cycle mode, no need for complicated and expensive PWR steam generators and the very complicated BWR reactor pressure vessel bottom. Moisture separators and steam dryers are inside the pressure vessel and secondary separators and dryers can be installed outside the reactor vessel, inside or outside the containment. The containment is a simple dry containment which allows easy entrance and inspections and also minor repairs during operation.

Figure 5: HP-BWR in a dry containment

Thanks to Hernan Tinoco of the Forsmark NPP and Joanna Peltonen of KTH for their valuable support.

ENS News, October 2007, Proceedings of the European Nuclear Conference (ENC) 2007, Brussels

![]()

© European Nuclear Society, 2008