European

Nuclear Society

e-news

Issue 19 Winter 2008

http://www.euronuclear.org/e-news/e-news-19/two-phase-flow.htm

Two Phase Flow

Test Loop Results for BWRFrigyes Reisch

Nuclear Power Safety, KTH, Royal Institute of Technology

Stockholm, Sweden

Seminar

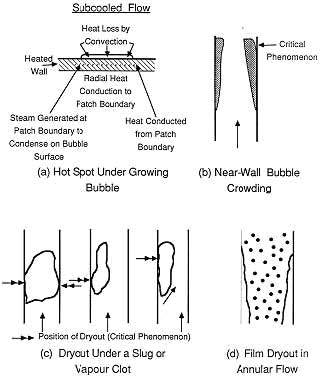

Normally the fuel surface is effectively cooled by boiling water. However if the heat flux exceeds a critical value the heat transfer from the fuel surface into the coolant deteriorates, with the result that drastically increased fuel surface temperature occurs. According to Michael L. Corradini University of Wisconsin, Madison WI the "mechanisms of critical heat flux" are:

a) Formation of hot spot under a growing bubble, near-wall bubble crowding and inhibition of vapor release. Here, when a bubble grows at the heated wall, a dry patch forms underneath the bubble as the micro-layer of liquid under the bubble evaporates. In this dry zone, the wall temperature rises due to the deterioration in heat transfer.

b) Near-wall bubble crowding and inhibition of vapor release: here, a 'bubble boundary layer' builds up on the surface and vapor generated by boiling at the surface must escape through this boundary layer. When the boundary layer becomes too crowded with bubbles, vapor escape is impossible and the surface becomes dry and overheated, giving rise to burnout.

c) Dryout under a slug or vapor clot. In plug or slug flow, the thin film surrounding the large bubble may dry out giving rise to localized overheating and hence burnout. Alternatively, a stationary vapor slug may be formed on the wall with a thin film of liquid separating it from the wall; in this case, localized drying out of this film given rise to overheating and burnout.

d) Film dryout in annular flow. Here, in annular flow, the liquid film dries out to evaporation and due to the partial entrainment of the liquid in the form of droplets in the vapor core.

Excessive fuel temperature can be caused e.g. by overpower or reduced coolant flow. With neutronics and thermal-hydraulic power oscillations when the duration of the power peaks are very short temporary over temperature can occur without causing fuel failures as the normal cooling can quickly recover.

To avoid excessive fuel temperature, the knowledge of the onset of the overheating phenomena is absolutely necessary, both at the design stage and for the safe operation of a reactor. There are complex correlation especially developed for specific fuel bundle designs. These correlatoins are containing; surface power, mass flow, system pressure and other parameters. While analyzing recent test results it was recognized that a single parameter the void is characterizing the onset of the overheating phenomena.CHF (Critical Heat Flux) Mechanisms

Figure 1. Critical Heat Flux Mechanisms

BWR fuel spacer

Measurements have been carried out in a two-phase flow test loop consisting of two heated concentric tubes, the central one representing a fuel rod while the outer pipe emanates the heating power corresponding to the surrounding fuel rods in a reactor core. This loop has been in operation for some thirty years to simulate thermal hydraulic conditions in Boiling Water Reactors. A wealth of data has accumulated during this time and has helped to enable BWRs to be operated safely and economically.

Test loop cross section

The results of the recent tests were studied to investigate the occurrence of the onset of the excessive temperature on the surface of the inner - and outer test tubes in htis annular flow system. The test covered the pressures of 30, 50 and 70 bar; sub-cooling 10° C and 40°C; mass velocities between 250 and 2250 kg/m2s and a total input power up to 580kW with uniform power distribution. The tests have been repeatedly performed with pin spacers, and 7 and 6 grid spacers. Then the test results were evaluated. To calculate the steam quality, the continuity - i.e. the heat and mass balance equations were applied. To calculate the void three known slip correlations; Kirilov, Thom and Zivi were used (Fig.1). Kirilov is the most recent one. The most important result is, that at the onset of the excessive surface temperature the void value changes merely between 0.88 to 0.99, while the steam quality changes in a wide range from 0.45 to 0.75 (Fig.2). This means that the occurrence of the onset of the excessive surface temperature is basically dependent on the void. The performed analysis shows the same results regardless which correlation is employed and are valid at all the actual pressures, subcooloings, mass flows, spacer types and their positioning along the test section. There has been an awareness of this however - according to the author - but it has not yet been explicitly outlined. This help to focus on the void when planning furher test loop experiments as well as when monitoring the safety of operating reactors and fuel design.

The awareness of this result helps with the design of a tool to avoid excessive fuel surface temperature and clad failure in operating reactors. To monitor the void during operation is not feasible, however from the measured parameters, power, power distribution, coolant flow, pressure etc. the steam quality everywhere in the core can be calculated continuously and the void can be deduced using steam quality versus void correlation from loop experiments. By using the constraints described here - limiting the permissible void content - damage of the fuel can be avoided.

Curiously it can be noted that an analytical model is described in the DOE rapport KAPL-P-000160 by Alajbegovic, et.al. The mathematics are applied for a Freon loop and the deduced figures coincide with the measurements from the experimental loop. The results are summarized in Figure 3. The abrupt increase of the temperature here too occurs when the void value reached around 90%.

Figure 3. Prediction of critical heat flux for Freon at p=1.5 bars, q ”= 190 kW/m2 at constant liquid velocity of 0.5 m/

© European Nuclear Society, 2008