European

Nuclear Society

e-news

Issue 9 Summer 2005

http://www.euronuclear.org/e-news/e-news-9/cez.htm

This year the Czech nuclear industry celebrates the twenty years of the day when the first of the four Dukovany’s nuclear reactors was put into operation. The Nuclear Power Plant (NPP) has been operated successfully since its commissioning, as we can infer from the various national and international assessment studies. In this period of anniversary, we ought to remember a few significant dates.

Activity |

Date |

| Start of reactor (first criticality) |

12th February 1985 |

| Connection of turbogenerátor 1 to electric grid |

24th February 1985 |

| Connection of turbogenerátor 2 to electric grid |

25th February 1985 |

| 100 % power |

26th March 1985 |

| Start of Unit1 test operation |

3rd May 1985 |

| Start of Unit1 commercial operation |

3rd November 1985 |

In the first year of operation, Dukovany NPP’s Unit 1 produced 2.4 billion KWh (TWh) and reached already 59.7 billion KWh (TWh)by the end of 2004. Such amount of electricity would be sufficient to supply all Czech households at their 2004 consumption level for over 50 months.

In 2004 the Czech Republic’s total electricity generation amounted to 84.3 billion KWh (TWh) and the share of Dukovany NPP’s four Units was 16.2%. Together with the second nuclear power plant of the country, Temelín NPP, the nuclear share in total electricity production in the CR was 31.2%

History

The history of the Dukovany NPP dates back to 1970 when the former Czechoslovakia

and USSR signed an intergovernmental agreement on the construction of two 1760

MW-nuclear power plants: one at Jaslovské Bohunice in Slovakia and the

second at Dukovany in South Moravia. The Dukovany site was chosen because of

the nearby pumping hydro power plant in Dalesice with the balancing reservoir

Mohelno, both located on the Jihlava River. The hydro system serves as a reservoir

of cooling water for the nuclear power plant.

Construction started in spring 1974

The construction of the NPP started in April 1974 but works were suspended between

1976 and 1978. During this period, the design was modified to fit the updated

model of the VVER 440 –V213. It was a very successful model of PWR reactors

based on previous Russian operating experience. The construction resumed in

late July 1978. The Czech national companies played a dominant role in the construction

of the NPP, and the manufacture and montage of the equipment. 85% of all equipment

was made in the Czechoslovakia incl. reactors, steam-generators, turbines, etc.

Companies such as Skoda, Vitkovice and Kralovopolska were the main suppliers.

In full capacity in 1997

The pressure vessel was fitted in the structure of Unit 1 in November 1982 and

the first criticality was achieved in February 1985. Full power was achieved

one month later. Next three Units were subsequently commissioned in 1986 and

1987. Dukovany NPP reached its full power of 1760 MW in July 1987. From the

beginning of its operation in 1985 to the end of 2004 the nuclear power plant

produced more than 238 billion KWh of electricity.

Nowadays

Over the whole period of its existence the Dukovany nuclear power plant has

featured high reliability, low rate of failures and high safety. The major asset

of the NPP is its contribution to fighting climate change. It saves 17 million

tons of CO2 a year that would be otherwise released into the atmosphere by burning

11 million tons of coal in thermal power plants.

Nuclear is the cheapest power source

Nuclear reactors are operated at full power in the long term for technical and

economic reasons. Refuelling is performed once a year and during this process

approximately one fifth of the fuel in the reactor is replaced. Since 1985 Dukovany

NPP has changed its fuel cycle from a 3-year cycle to a 5-year cycle and such

a change has reduced the volume of spent nuclear fuel by 5.3 tons per Unit and

per year. Such a modification has a significant economic impact, resulting in

cutting down fuel and storage costs. By the end of 2004, Dukovany NPP had already

saved more than 6 billion CZK.

The advanced nuclear fuel with a 5-year cycle was used at Dukovany NPP for the first time in 2003 in Unit 2 and later on in Units 1 and 4. This year, during the refuelling of Unit 3, a completely new type of fuel is used for the first time. This new fuel is characterised by reduction of Uranium 235 enrichment from 4.38% to 4.25% while maintaining the same fuel assembly performance. Full transition of all four Dukovany Units to the 5-year cycle will be accomplished by 2008. The Russian company TVEL from Elektrostal factory (near Moscow) is a fuel supplier for Dukovany NPP and the contract for the advanced fuel is valid until 2011.

Nuclear Safety

Nuclear safety is a basic requirement of the Dukovany NPP operation. It consists

of a set of technical and organisational requirements, aiming to ensure that

the nuclear fission process and corresponding release of radioactivity remain

under control whatever the conditions. Apart from nuclear safety, the power

plant staff closely supervises radiation safety. Radiation protection of human

beings and of the environment is ensured by protecting them against consequences

of ionising radiation and contact with radioactive substances.

Trained and highly qualified personnel

The outstanding operation of Dukovany NPP is not only a result of designers,

builders and manufacturers’ efforts. A highly trained and qualified operation

personnel is working at Dukovany NPP. Every employee has to successfully go

through health examinations and regularly repeated psychological tests. Provided

that he/she fulfils all general qualification requirements, he/she is trained

in the Training Centre for the job. The most specific training is provided for

the licensed operators in main control rooms whose expertise is examined every

two years by a state examination committee of top experts in the nuclear sphere.

All in all 17% of workers have trade and craft qualification, 49% high school

qualification and 33% university education.

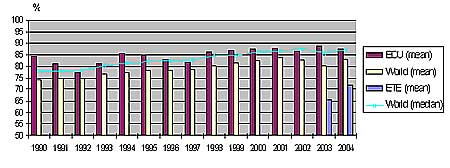

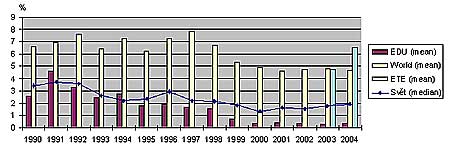

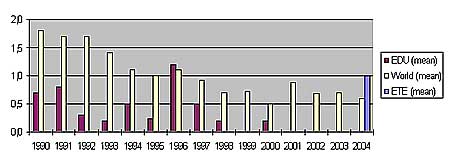

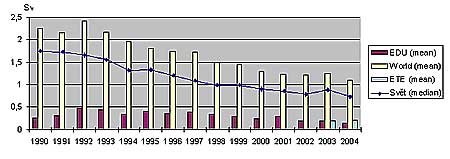

Among the best performers

According to expert assessments, Dukovany NPP belongs to the best performers

among nuclear power plants worldwide. With regard to a number of parameters

and indicators, Dukovany NPP is above the European average. Nuclear operators

worldwide use performance indicators of WANO (World Association of Nuclear Operators),

based on which Dukovany Units are in the first 20% of all reactors.

Public acceptance

The population living near the nuclear power plant is in favour of nuclear power.

According to an opinion poll, about 90 % of the inhabitants living in a zone

of 20 kilometres around the plant back the operation of the nuclear power plant.

Future

As it was proved, the equipment of Dukovany NPP is capable of being operated

much longer than 30 years than initially designed. Lifetime analysis and the

aging of equipment showed that the lifetime of the vital parts, particularly

reactor vessels are from 70 to 140 years (on different Units). Other equipment

is in a similar shape. That is why the CEZ management decided to extend the

lifetime of Dukovany NPP to forty years, i.e. to 2025, at least. Based on this

decision a Harmonisation Programme has been developed which sets up a number

of particular projects (80) incl. equipment, licensing, documentation, PR, personnel,

competitiveness and management.

EDU = Dukovany NPP, ETE = Temelín NPP

Stage / Unit |

1. |

2. |

3. |

4. |

Positioning of RPV |

26.12.1982 |

22.4.1983 |

27.2.1985 |

20.12.1985 |

First hydro-testing |

25.11.1983 |

6.4.1984 |

12.3.1986 |

2.9.1986 |

Minimum |

12.2.1985 |

23.1.1986

|

28.10.1986 |

1.6.1987 |

First connection to the grid |

24.2.1985 |

30.1.1986

|

14.11.1986 |

11.6.1987 |

100% Power |

26.3.1985 |

21.2.1986 |

7.12.1986 |

3.7.1987 |

Test operation |

3.5.1985 |

20.3.1986 |

20.12.1986 |

19.7.1987 |

Commercial operation |

3.11.1985 |

21.9.1986

|

20.6.1987

|

19.1.1988 |

| Total installed capacity |

1760 MWe |

| Thermal efficiency |

32 % |

| Total efficiency |

29,2 % |

PRIMARY CIRCUIT |

|

Type of reactor |

PWR |

Number of reactors |

4 |

Fuel |

Slightly enriched Uranium U 235 |

Mass of fuel |

42 000 kg |

moderator |

Water with boric acid |

Number of controlled rods |

37 |

Number of fuel assemblies |

312 |

Steamgenerator type |

Horizontal, cylindrical |

Number of SG per Unit |

6 |

Pressuriser type |

cylindrical, vertical |

Number of pressurisers per Unit |

1 |

| SECONDARY CIRCUIT |

|

Turbine type |

3 parts, impulse, condensing turbine |

Turbine power |

220 MWe |

Rotation speed |

3000 rpm |

Number of TGs per Unit |

2 |

Generator |

Double-current g., synchronous atlernator |

Number of Generators per Unit |

2 |

1985 |

1986 |

1987 |

1988 |

1989 |

|

Unit 1 |

2397 |

2853 |

2768 |

2715 |

3156 |

Unit 2 |

|

2988 |

2855 |

2956 |

3216 |

Unit 3 |

|

308 |

3325 |

3193 |

2864 |

Unit 4 |

|

|

1753 |

2952 |

3182 |

Total in year |

2397 |

6149 |

10701 |

11816 |

12418 |

Total (GWh) |

2397 |

8546 |

19247 |

31063 |

43481 |

1990 |

1991 |

1992 |

1993 |

1994 |

|

|

|

3180 |

2742 |

3173 |

3240 |

3279 |

Unit 2 |

3021 |

3098 |

2831 |

3257 |

3094 |

Unit 3 |

3187 |

3196 |

2918 |

3190 |

3344 |

Unit 4 |

3197 |

3096 |

3328 |

2940 |

3260 |

Total in year |

12585 |

12132 |

12250 |

12627 |

12977 |

Total (GWh) |

56066 |

68198 |

80448 |

93075 |

106052 |

1995 |

1996 |

1997 |

1998 |

1999 |

|

Unit 1 |

2966 |

3353 |

3296 |

3176 |

3092 |

Unit 2 |

3263 |

3019 |

3145 |

3423 |

3411 |

Unit 3 |

2690 |

3066 |

2905 |

3298 |

3464 |

Unit 4 |

3311 |

3412 |

3149 |

3281 |

3390 |

Total in year |

12230 |

12850 |

12494 |

13178 |

13357 |

| Total(GWh) |

118282 |

131132 |

143626 |

156804 |

170161 |

2000 |

2001 |

2002 |

2003 |

2004 |

|

Unit 1 |

3553 |

3557 |

3492 |

3240 |

3241 |

Unit 2 |

3161 |

3341 |

3378 |

3474 |

3297 |

Unit 3 |

3413 |

3214 |

3487 |

3506 |

3530 |

Unit 4 |

3461 |

3482 |

2941 |

3535 |

3565 |

Total in year |

13588 |

13593 |

13299 |

13755 |

13632 |

Total(GWh) |

183748 |

197324 |

210623 |

224396 |

238028 |

![]()

© European Nuclear Society, 2005