Education & Training

TRIGA Reactor in Vienna

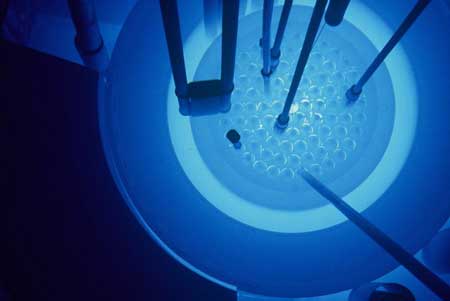

The Chernobyl accident in 1986 further reinforced the Austrian anti-nuclear policy adopted in 1978 through legislation prohibiting nuclear power production. Since that time, the country has been facing a strong anti-nuclear political environment. Out of its three operating research reactors, two were permanently shut down in 1999 and 2005 for various reasons. The only remaining research reactor is the TRIGA Mark II which is operated by the Vienna University of Technology/Atominstitut (VUT/ATI). The ATI operates a TRIGA Mark II research reactor since March 1962 with a thermal power of 250 kW which is today the only operating research reactor in Austria. The reactor is equipped with a thermal column, a radiographic collimator, four beam tubes and three in-core pneumatic transfer systems. Inside the core, there are about 16 irradiation positions for irradiation experiments while outside the core, the four beam tubes supply neutron for basic and applied neutron research.

Title and short description of possible experiments at the TRIGA reactor Vienna:

-

Thermal neutron flux measurement: Thin Au foils are irradiated in the TRIGA core at 10 W radially and vertically both Cd-covered and uncovered, from this Cd-difference measurement the radial and axial neutron flux distribution is determined.

Influence of void coefficient on reactor power: At 10 W reactor power a small container with different air volumes is pulled axially through the reactor core while the reactor is in automatic operation mode. The influence of volume and position in the core on reactivity is determined.

Critical experiment: Then fuel elements are removed from the reactor core and consecutively re-loaded; the neutron count rate is measured after each step. At each step measurements are performed with all control rods up and then down. Criticality is reached with all control rods up after reloading of five fuel elements.

Control rod calibration: One control rod is calibrated by removing it stepwise from the critical core and measuring the resulting reactor period. Sing the in-hour equation the respective reactivity value is determined.

Reactivity values of fuel elements in different core positions: While the reactor is on automatic control with 10 W from each of the five fuel ring positions one fuel element is removed. The loss of reactivity is compensated by the movement of the regulating rod. From the rod position difference and using the rod calibration curve the reactivity value of the fuel element in different core positions can be determined.

Reactor power calibration and temperature coefficient of reactivity: The reactor is operated at 10 Watts, rod positions, water- and fuel temperature is noted, then the reactor power is raised to 100kW again the values are noted. From the difference in rod position and fuel temperature the fuel temperature coefficient can be determined. Then reactor is operated for 90 min only with convection cooling and the increase of water temperature is monitored. Comparing the temperature increase with the value from a previous e calibration the thermal reactor power can be determined.

-

Demonstration of a prompt critical power excursion: Due to the strong negative temperature coefficient of reactivity TRIGA reactors allow prompt critical excursion to 1000 times the normal power mode without any damage to the core. This is demonstrated using a pneumatic rod which is removed promptly from the critical core, typical power levels of 250 to 300 MW are reached for a time period of about 40 ms

-

Introduction into typical research reactor instrumentation: An introduction to the instrumentation of the TRIGA Mark II reactor is given, towards the end the participants will be able to start up the reactor to various power levels.

-

Calibration of the nuclear channels: The nuclear and temperature channels are calibrated according to given procedures, alarm and scram settings are verified.

-

Measurement of control rod drop times: The three control rod drop times are checked according to given procedures, the individual rod drop time is measured from different rod positions.

-

A compensated ionisation chamber (CIC) is used to determine the optimal compensation voltage and to measure the A-V characteristics at different power levels.

-

Fission chambers: A fission chamber is used to set the discriminator between gamma- and neutron signal and to determine the range of neutrons outside the core.

-

Self-powered neutron detectors: A self-powered neutron detectors is exposed in the core centre and it´s activation and decay is monitored. This allows to determine the type of emitter material.

-

NPP Simulator Program (PWR): Using an IAEA simulator program for PWR type reactors a cold start up is carried out, followed by power changes and selected incident simulation.

Verification of the radiation level during reactor operation: Using various radiation detectors the radiation field at different reactor areas are verified.

Control rod Calibration in the subcritical range: The safety rod will be calibrated in the subcritical range by cross-calibration using the reactivity data of the regulating rod. In this case the safety rod is lifted in small steps from the zero position and the count rate increase is measured with a fission chamber.

-

Safeguards mock-up inspection

-

Demonstration fuel handling

-

Gamma-spectrometry with various fuel samples

The TRIGA Mark-II Reactor The TRIGA Mark-II Reactor

|