European

Nuclear Society

e-news

Issue 18 Autumn 2007

http://www.euronuclear.org/e-news/e-news-18/HP_BWR.htm

Some four hundred Boiling Water Reactors (BWR) and Pressurized Water Reactors (PWR) have been in operation for several decades. The present concept, the High Pressure Boiling Water Reactor (HP-BWR), makes use of this operating experience. The best parts of the two reactor types are used and the troublesome components are left out. This means improved safety. The increased thermal efficiency is beneficial to the environment as less cooling water is released per produced kWh. With some modifications the used components can be used to make this design cost effective and possible to achieve in the currently not too distant future.

Since the 1950s several hundred Boiling Water and Pressurized Water Reactors (BWRs and PWRs) in use. There is a wealth of operating experience. During this have been time many difficulties occurred with a number of important components. This concept, the High Pressure – Boiling Water Reactor (HP-BWR) offers a solution to use the best parts from each type (BWR and PWR) and leave out the troublesome components. This means an important increase of safety. As an extra benefit, also increased efficiency attained beneficial for the environment as less cooling water is released per produced kWh. The HP-BWR is using –with some modifications- currently manufactured parts making this a cost effective, realistic concept.

The High Pressure Boiling Water Reactor (HP-BWR) offers improved nuclear safety and less damage to the environment. The HP-BWR is an environmentally friendly, effective alternative.

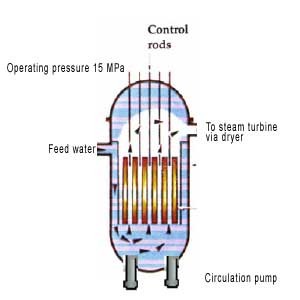

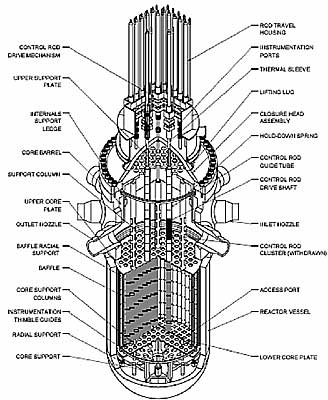

The HP-BWR uses a modified PWR reactor vessel and BWR type fuel and control rods. However, here the cruciform control rods are gravity operated with ample space between the crosses and the fuel boxes. The control roads are manoeuvred electromagnetically, which means that they will drop into the core when there is a loss of electrical power as in the PWRs. The traditional PWR control rods are finger shaped and are surrounded by a tube with a minimum of clearance. The traditional BWR control rods are operated from below with hydraulic pressure. Therefore, at the bottom of the traditional BWR reactor vessel there are a great number of penetration points for the control rods. Directly below the reactor vessel there is an elaborate system of numerous high pressure hydraulic pipes to actuate the control rods. Taking the best fro and leaving out the drawbacks of both the traditional BWR and PWR systems is a substantial safety improvement.

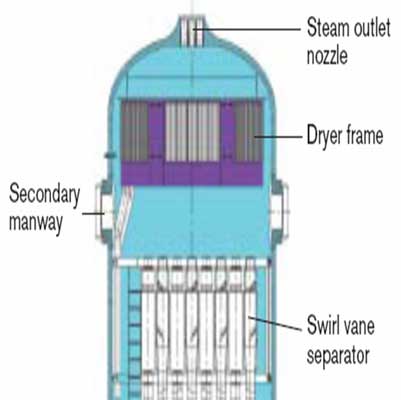

All the pipe connections to the reactor vessel are well above the reactor core. This allows the omission of core spray. The moisture separators and steam dryers are outside the reactor vessel, leaving free space for the control rods.

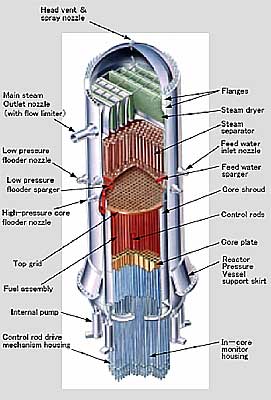

Internal circulation pumps. These allow the use of orifices at the inlet of the fuel boxes so that the one-phase pressure drop will predominate over the two-phase pressure drop. This reduces the risk of hydrodynamic oscillations. However, if suitable methods are found to facilitate natural circulation even the circulation pumps can be left out.

The use of the HP-BWR means improved Carnot cycle thermal efficiency up to about ~40% instead of about ~30%. The reason is that the HP-BWR steam temperature corresponds to 15MPa while the traditional BWR’s steam temperature corresponds to 7MPa and the traditional PWR’s steam temperature corresponds to 6MPa. The HP-BWR is lenient to the environment as less damaging cooling water is released per produced kWh to the recipient, sea or river or to the air via a cooling tower.

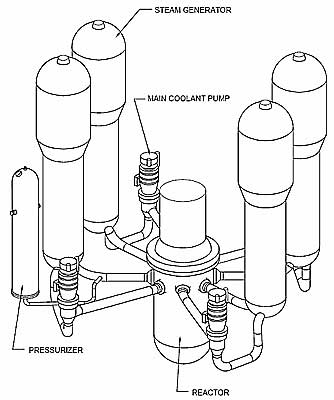

Using direct cycle the system is simplified. Still, the usual PWR steam lines can be used through the containment wall to the turbine. A great advantage is that the complicated and costly steam generators are left out.

The moisture separators and the steam dryers are outside the reactor vessel in the containment instead of the huge troublesome steam generators.

Simple dry containment is used instead of the complicated, inert, pressure suppression wet containment which requires a great deal of surveillance.

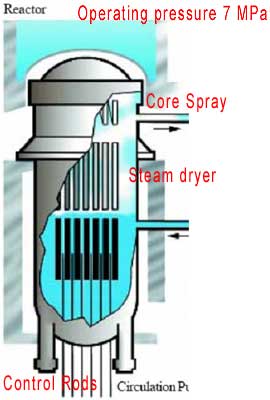

The basic principles of the traditional Boiling Water reactor are well known

As there are pipe connections to the reactor vessel below the reactor core, a pipe break can empty the vessel leaving the core uncovered, without the cooling water. Therefore, a core spray is required. This is a common feature for the BWRs with external circulation pumps or jet pumps. However, this draw back is eliminated at a later design stage with the Advanced Boiling Water Reactor, ABWR. All BWR control rods are inserted to the core using hydraulic power; some with electric motors too. This makes the lower part of the rector both inside and outside the bottom of the reactor vessel extremely elaborate. To make things worse, in the past, cracks, corrosion and leakage occurred at the penetrations at the lower part of the reactor vessel.

Traditional Advanced Boiling Water Reactor (Hitachi–ABWR)

The huge reactor vessel would require an enormous dry containment building. Therefore, a pressure suppression containment system is used instead. The containment is separated into two parts, the upper dry well and the lower wet well with the suppression pool. If the separation is not perfectly leak-tight the wet well cannot fulfil its function to suppress the pressure in the dry well in case of a pipe break. Further complication is that the traditional BWR containment operates inertly, making difficult the entrance into it.

The nice thing about the BWR is that it operates in direct cycle mode without the troublesome steam generators.

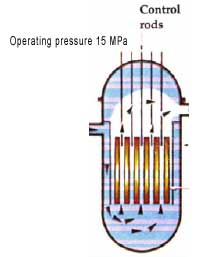

Most of the world’s operating reactors are traditional PWRs.

The control rods are operated from above. Undoubtedly some leakages were observed at the penetrations which in a few cases led to the need to replace the reactor pressure vessel head.

The simple electromagnetic devices which manoeuvre the rods worked reliably. This assures a high degree of safety. A basically continuous, uninterrupted bottom of the reactor vessel avoids any suspicions of its integrity.

A four-loop Westighouse plant has four steam generators, four reactor coolant pumps, and a pressurizer. The four-loop units in the United States are Braidwood 1 and 2, Byron 1 and 2, Callaway, Catawba 1 and 2, Comanche Peak 1 and 2, D.C. Cook 1 and 2, Diablo Canyon 1 and 2, Indian Point 2 and 3, McGuire 1 and 2, Millestone 3, Salem 1 and 2, Seabrook, Sequoyah 1 and 2, South Texas Project 1 and 2, Vogtle 1 and 2, Watts Bar 1, and Wolf Creek. Each of these plants has 193 fuel assemblies arranged inside a reactor vessel that has an internal diameter of 173 inches (except South Texas has an internal diameter of 167 inches). The fuel assemblies are arranged in 17 x 17 array except for Cook and Indian Point, which have 15 x 15 fuel. The electrical output of these plants ranges from 950 to 1250 megawatts.

The curse of the traditional PWRs is their steam generators. These complicated and costly huge pieces of equipment are disappointingly short lived because of the corrosion of the internal tubes, which can cause leaks. The plant owners used to change them after some fifteen years. An extremely expensive and troublesome and also time consuming operation.

In the upper part of the steam generators there is the moisture separator and the steam dryer. The HP-BWR is “borrowing” this equipment which can be used without the troublesome steam generators.

All university text books written for nuclear engineering students contain detailed descriptions of both Boiling Water Reactors and Pressurized Water Reactors. Also manufacturers in Europe, Asia and America publish data about their designs. There is also a wealth of information about BWRs and PWRs on the internet.

![]()

© European Nuclear Society, 2007