|

|

Issue No.10 Autumn

|

| ENS News |

| ENS Events |

| Member Societies & Corporate Members |

YGN Report |

| European Institutions |

| ENS World News |

ENS Members |

| Links to ENS Member

Societies Links to ENS Corporate Members Editorial staff ______________________ |

|

| _____________________ |

| _____________________ |

| _____________________ |

|

|

|

|

In November 2000, TVO applied to the Finnish Ministry of Trade and Industry for a decision in principle according to the Finnish Nuclear Energy Act. This had been preceded by environmental impact assessments prepared for the two candidate sites – Olkiluoto in southwestern Finland and Loviisa on the south coast – and reviewed by the Ministry. In January 2002, after an extensive official consultation procedure, the Finnish Government's Council of State reached its decision in principle in favor of a new nuclear unit. The decision was ratified by Parliament in May of that year. |

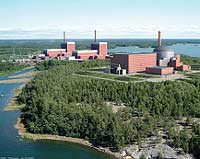

Affordable climate protection: the EPR (foreground) will become a reality at Olkiluoto in Finland in 2009. |

Power generating costs of new nuclear power plants according to Professor Risto Tarjanne, Lappeenranta University of Technology.

International Competition

In October 2002, four months after ratification by Parliament, TVO issued a request for proposals for Finland’s fifth nuclear unit, which called for a PWR or a boiling water reactor (BWR) with a rated capacity of between 1000 and 1600 MW.

On March 31, 2003, TVO received proposals from various vendors, including Framatome ANP that had formed a consortium with Siemens. After carefully evaluating these proposals and clarifying further technical aspects with all of the bidders, TVO announced on October 18, 2003 that the Framatome ANP/Siemens Consortium was the preferred bidder. TVO had concluded that, in terms of future power generating costs, the EPR represented the most cost-effective solution. At the same time, it was announced that the new power plant unit would be built at the Olkiluoto site.

On December 18, 2003, the contract was signed in Helsinki. It officially came into effect on January 1, 2004. In parallel with this, the documentation required for obtaining a construction license under the Finnish Nuclear Energy Act was submitted to the Finnish Radiation and Nuclear Safety Authority (STUK) and initial preparation of the construction site was commenced. After reviewing these documents, STUK concluded in its preliminary safety assessment for the Finnish Ministry of Trade and Industry that it did not see any safety-related issues opposing issuance of the nuclear construction license. STUK emphasized that the evolutionary design of the EPR had been further improved by AREVA compared to the previous product lines. This led to the Finnish Government granting the construction license on February 17, 2005.

Project Organization

Framatome ANP's scope of supply and services encompasses the nuclear island, including the design, procurement and delivery of all of its mechanical and electrical equipment, installation and initial startup, the fuel assemblies for the first core and an EPR simulator. Furthermore, the company is responsible for overall project coordination as well as for functional and technical integration of the overall plant, and is also head of the consortium.

Siemens is responsible for supplying the conventional island, including the design, procurement and supply of all of its electrical and mechanical equipment, as well as the turbine and generator protection and control systems, and installation and initial startup of the turbine generator set.

A significant proportion of the engineering, construction and erection work, as well as the supply of mechanical and electrical equipment, will be placed with subcontractors after an international bidding process. Of course, Finnish companies will also be able to participate in this bidding. If their proposals should prove to be competitive at an international level they will likewise be given consideration during the proposal evaluation phase so that a large portion of the supplies and services for the project could be remaining in the country. Quite appreciable work packages have already been contracted out to Finnish companies. They are also profiting from the fact that orders awarded to companies outside Finland lead, in turn, to work being placed with Finnish subcontractors so that, in the end, a substantial portion of the total project value will be remaining with Finnish industry. Further requests for proposals are scheduled to be issued in the course of this year as well as at the beginning of the next year.

Current Project Status

Following completion of the excavation work that had been carried out by Finnish contractors employed by the customer, the Framatome ANP/Siemens Consortium took over the site on February 1, 2005.

Early in the summer of 2004, the consortium had already placed several major orders with Finnish companies. These orders covered the concrete mixing plant and the detailed design of the base slab of the reactor building complex as well as construction of the common raft foundation. In addition to this, supplies for the site infrastructure (office building and canteen, etc.) were also ordered from Finnish companies. The concrete mixing plant, which was erected directly on site, will have supplied a total of around 250,000 cubic meters of concrete via permanently installed pipelines and concrete mixer trucks by the time construction is finished. It was placed in operation in the spring of 2005 so that work could be started on pouring the leveling concrete.

In 2004, an order was also placed for a heavy-lift crane with a load-carrying capacity of 1600 metric tons required for the construction and erection work.

The largest single orders for construction work went to companies based in France and Germany. However, significant portions of these volumes of work will be coming back again to Finnish contractors.

|

|

|

Birth of the EPR and its Development Goals

Framatome of France and Germany’s Siemens began developing the EPR in 1992 on behalf of and with significant support from the French national utility Electricité de France (EDF) and leading German utilities. The project was closely monitored and supported by licensing authorities and independent inspection agencies in both countries to ensure the EPR's licensability in France and Germany. Through the Olkiluoto 3 project, the EPR is now being fully licensed for the first time by the Finnish authorities.

The EPR builds on proven technologies deployed in the two countries' most recently built nuclear power plants – the French N4-series units and the German Konvoi-series plants – and constitutes an evolutionary concept based on these designs. This enables full use to be made of all of the reactor construction and operating experience gained not only in France and Germany – with their total of 2070 reactor operating hours – but also worldwide. Guiding principles in the design process included the requirements elaborated by European and US electric utilities for future nuclear power plants, as well as joint recommendations of the French and German licensing authorities.

The key development goals were:

-

To further increase safety and, at the same time,

-

To further improve economic performance.

Even Greater Safety

Safety levels at nuclear power plants have been constantly improved in the past. The EPR, a nuclear reactor of the third generation, represents yet another step forward in terms of safety technology, offering in particular the following features:

-

Improved accident prevention, to reduce the probability of core damage even further,

-

Improved accident control, to ensure that – in the extremely unlikely event of a core melt accident – the radioactivity is retained inside the containment and the consequences of such an accident remain restricted to the plant itself,

-

Improved protection against aircraft crash, including large commercial jetliners.

Measures providing superior accident prevention capability include a larger water inventory in the reactor coolant system and the steam generators, a lower core power density, and high safety-system reliability thanks to quadruple redundancy and strict physical separation of all four safety system trains. The plant design also incorporates state-of-the-art digital instrumentation & control (I&C) systems along with optimized man-machine interfaces.

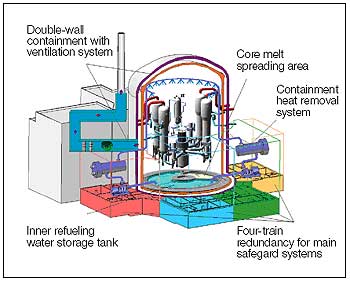

If a core melt accident should occur despite all of the accident prevention measures deployed, the molten core material (corium) will be collected and cooled in a specially designed corium spreading area located underneath the reactor pressure vessel but still inside the containment. The extremely robust double-walled containment will reliably keep any radioactivity confined inside the building.

Probabilistic safety analyses were incorporated from the outset into the design process in order to determine those accident sequences capable of leading to severe core damage or significant releases of radioactivity, to evaluate their probability of occurrence and to implement design features that would further reduce their contribution to the overall risk.

Enhanced Competitiveness

The following factors contribute towards making the EPR's power generating costs even lower than those of the most recently built nuclear power plants currently in operation:

-

Larger net electric output of around 1600 MW: this leads to lower specific construction costs

-

Higher secondary-side pressure of 78 bar: this in conjunction with an optimized turbine design results in an efficiency of more than 37% under Finnish conditions – the highest efficiency of any light water reactor plant in the world

-

Shorter construction period of 48 months

-

Extended design plant service life of 60 years

-

Higher fuel utilization with a discharge burnup of more than 60 GWd/t: this means reduced uranium consumption and lower spent fuel management costs

-

Greater ease of maintenance thanks to improved accessibility and standardization, with preventive maintenance being possible while the plant is on line

-

Shorter refueling outages leading to higher plant availability.

Factors aimed at ensuring the longest possible periods of uninterrupted power operation with minimal downtime comprise:

-

Fuel operating cycles of up to 24 months

-

Short refueling outages, even when extensive maintenance work is necessary

-

Plant availability ratings of more than 90%.

The EPR Design

The reactor building, two of the four adjacent safeguard buildings and the fuel building will be of double-walled design to enable them to withstand the loads induced by natural and external man-made hazards (particularly aircraft crash).

The EPR has a slightly higher reactor thermal output than other PWRs currently in operation. The deployment of steam generators with economizer sections along with an advanced steam turbine design will lead to higher efficiency. In addition, core coolant flow has been maximized based on operating experience.

Safety systems directly connected to the reactor coolant system which serve to inject coolant into the system in the event of a loss-of-coolant accident (LOCA) are designed with quadruple redundancy.

The emergency core cooling systems comprise four passive accumulators as well as four low- and intermediate-pressure safety injection systems.

In addition to the systems for residual heat removal that are connected directly to the reactor coolant system, a further system designed to assure heat removal in the event of loss of normal feedwater supply is connected to the secondary system. This consists of a four-train emergency feedwater system that supplies water to each steam generator. The emergency feedwater system on the secondary side is equipped with electric-motor-driven pumps that can be powered, if necessary, by the unit's four large emergency diesel generators. In addition, the plant is also equipped with small, separate diesel generators to ensure that feedwater supply to the steam generators is guaranteed even in the event of simultaneous failure of all four of the large emergency diesels.

In the steam generators, the heat generated in the reactor is used to produce steam for driving the turbine. This steam is then condensed in the turbine condenser. If the condenser should be unavailable due to loss of the main heat sink, the excess steam can be directly discharged to the atmosphere from the steam generators.

The in-containment refueling water storage tank serves to store water for emergency core cooling and accommodates any leakage water discharged via a pipe break in the reactor coolant system.

Major safety features of the EPR.

TECHNICAL DATA |

|

Reactor thermal output: |

4300 MW |

Net electric output: |

approx. 1600 MW |

Main steam pressure: |

78 bar |

Main steam temperature: |

290°C |

Reactor pressure vessel height: |

13 m |

Reactor core height: |

4.2 m |

Number of fuel assemblies: |

241 |

Uranium inventory in reactor: |

128 t UO2 |

Number of control rods: |

89 |

Containment height: |

63 m |

Containment inside width: |

49 m |

Outer Containment wall thickness: |

2 m |

Enhanced Safeguards

To meet the requirements of the nuclear safety authorities, additional provisions for preventing beyond-design events were incorporated right from the start into the EPR design. These comprise, in particular, backup functions deployed on a systematic basis to further enhance safeguards for accident prevention. If an entire accident control function should fail, diverse actions will be implemented to achieve the same safety objective. What does this mean in concrete terms? For example, if all four redundant intermediate-pressure safety injection trains should be lost after a small-break LOCA, the residual heat from the reactor core can alternatively be removed via the secondary system, and the pressure reduced to a level at which the passive accumulators and low-pressure safety injection pumps can feed emergency coolant into the reactor. Hence, even in the extremely unlikely event of complete loss of all four redundant subsystems, the accident can still be controlled in such a way that destruction of the core is ruled out.

The safety authorities require that, despite all enhancements incorporated into the EPR design for accident prevention, provisions nevertheless be made to control all events that could possibly lead to melting of the core following a postulated loss of all safety systems, the aim of this being to prevent catastrophic impacts on the environment. In the case of the EPR this primarily meant providing engineered safeguards that would prevent destruction of the containment in the event of a postulated (hypothetical) core melt accident. These safeguards comprise, in particular, reactor coolant system depressurization, a special reactor pit design, core melt stabilization, the design of the containment, containment heat removal and hydrogen reduction.

Better Radiation Protection for Personnel

In the course of designing the EPR, improvements were also made to the protection of operating and maintenance personnel against radiation. The target is a collective radiation dose of less than 0.4 person-Sieverts (pSv) per reactor unit and year (by way of comparison: up until now the limit in the West has been 1 pSv).

Nuclear Power Has a Future

The construction of Olkiluoto 3 in Finland has sparked off discussions about new construction projects in other European countries as well. The decision made by the private investor TVO to build a new nuclear power plant underscores the fact that nuclear technology plays an important role in liberalized power markets as an economical solution for CO2-free base-load power generation. The French utility Electricité de France (EDF) likewise decided – in October 2004 – to construct an EPR at Flamanville in Normandy. The key concern in France is to ensure the availability of a reliable energy technology in the long term: the project at Flamanville is to serve as a basis for a new series of nuclear units to replace French plants reaching the ends of their service lives from 2020 onwards.

The USA is following a similar strategy and has made a long-term commitment to nuclear energy. The service lives of many of its nuclear power plants are currently being extended and in addition the Bush Administration, together with the US utilities, is actively pursuing plans to launch the construction of a new nuclear unit before the end of this decade. In Asia, too, nuclear energy's share of the power-generating market is being deliberately expanded: China alone is planning to construct more than 30 GW of additional nuclear-based power-generating capacity by the year 2020, which means around 20 new state-of-the-art reactors.

Energy experts predict that the demand for new and replacement generating capacity in the Central and Western European power plant market will reach 400,000 MW by 2020, with the demand for new capacity set to reach similar levels in Eastern Europe. A significant proportion of this additional capacity will be needed for base-load service. Thanks to its economic efficiency, climate-friendliness and long-term reliability, nuclear power will continue to play a crucial role in the energy mix.

With the EPR, AREVA is in an excellent position to meet the needs of this large market, just as the Finnish contract – won in the face of stiff international competition – has demonstrated.

Rüdiger Leverenz,

Framatome ANP GmbH,

AREVA Group

ruediger.leverenz@framatome-anp.com

|

Dr. Ulrich Giese |

|

| |