Resumé of Swiss Nuclear Society´s

Autumn Seminar, 2006

by Dr. Peter Leister, Vice-President of the Swiss

Nuclear Society and of the European Nuclear Society

Would it be profitable for Switzerland to enter

into the hydrogen economy?

The seminar’s focus was on the substitution

of fossil fuel based energy for heating purposes using hydrogen

as the energy carrier. Bearing in mind that the seminar took place

last autumn, to publish a resumé now – when the two

parts of the UN Climate Change reports were only recently released

– re-enforces the seminar's original focus. Political and

economical aspects like independence from imports and stability

of fuel prices coincide very much with the requirements for environment

protection and the inevitable obligation to reduce CO2

emissions anywhere in the world, even in Switzerland.

This country imported, in 2005, 610 PJ of fossil

energy for heating, 503 PJ of which came from oil and 107 PJ from

natural gas .

Issues such as the building blocks of the hydrogen

technologies required to replace this amount of fossil fuel, their

availability and reliability were addressed by the different presentations

during the seminar.

The authors of the contributions to this seminar

represent a reservoir of international know-how of the hydrogen

economy in view of H2 production by conventional and

advanced processes (Linde, General Atomics, Le Commissariat à

l'Energie Atomique). Some represent utilities already operating

successfully stationary fuel cells (EnBW) or research institutions

participating in the international Generation IV Initiative Forum

(GIF). The GIF is driving forward high temperature reactor technology

towards its successful application as a heat source forH2

production or for desalination (Paul Scherrer Institute ) or for

use by an international engineering company at any kind of power

generation plant (Colenco).

Most of the presentations were given in German

but several were in English. Access to all of the contributions

is possible via the home page of the Swiss Nuclear Society at:

www.sns-online.ch/fs2007.

The lectures presented in the seminar followed

a logical sequence starting with an overview over the current

Swiss energy balance, a definition of the building blocks of a

hydrogen economy, its requirements and constraints and progressing

to a view of what Switzerland has contributed to the further development

of modern hydrogen technologies. Moreover, experiences obtained

with an initial industrial-scale application were described. A

major part of the seminar was dedicated to high temperature processes

for hydrogen production and the corresponding heat sources via

the high temperature nuclear gas cooled reactors, its further

development and programmes for improving materials were dicussed.

Last but not least, cost calculations for building up a hydrogen

economy in the transport sector, as well as for stationary purposes,

were presented.

A. Böhner presented data

on Swiss [presentation 1] energy consumption and production based

on how the various energy carriers in the different consumption

areas offer potential for being replaced by hydrogen and what

would be an acceptable technological scenario for using centrally-generated

hydrogen to replace imported fossil fuel especially, natural gas

for heating Swiss households, public buildings and heat consuming

industrial processes. He presented a strategy for the installation

of a hydrogen economy and identified its risks and merits. The

results of his economical calculations are mentioned at the end

of this resumé.

P. Dietrich then explained [presentation

2] which Swiss know-how is available and applicable to a hydrogen

economy scenario based on fuel cells. Various Swiss institutions

are involved in the further development of components for conventional

solar energy based H2production, for mobile and stationary

fuel cell technology and for H2 storage technologies.

For example, Swiss PSI and Material Research EMPA co-operate in

the area of metal hydrate storages for hydrogen - a very promising

technology. When it comes to an industrial-scale demonstration

for mobile applications this technology has already been used

for snow track vehicles and for the Michelin/PSI HYLIGHT-Car®.

Predictions about when the industrial application of large-scale

stationary metal hydrate storages is likely to be on stream range

from a period of between 10 to 15 years.

An overview of how state-of-the-art stationary

fuel cells can supply apartment buildings, hospitals, etc. by

simultaneously producing power and heat production on an industrial

scale was presented by B. Heyder in presentation

3. He emphasised that this kind of technology is a mature one

based on natural gas being fed into the fuel cells. If hydrogen

could be switched over to immediately, its greater efficiency

would be clear for all to see.

R. Schiffbauer dedicated presentation

4 to state-of-the-art industrial hydrogen production, pointing

out that hydrogen production is a very traditional industry that

has worked profitably for more than 100 years. To date, hydrogen

is not so much used as an energy carrier but more as a raw material

for chemical processes like steam reforming. Furthermore, the

distribution of hydrogen via pipelines has proven to be a very

safe technology for many decades since the last third of the 19th

century, when the gas mains of larger cities distributed gas to

households that contained a hydrogen content of more than 50%.

For more than 40 years pipelines conveying pure hydrogen have

been maintained very safely in European industrial centres like

the Ruhr and the area around Lille, France. These pipelines are

several hundred kilometers long. Even today existing natural gas

pipelines can be converted to hydrogen distribution without much

of an effort. Indeed, the transition from pure natural gas to

hydrogen operation would not create major technical problems.

Introducing a hydrogen economy would hence not require gas and

hydrogen pipelines in parallel during a transitional period.

Hydrogen production by steam reforming of hydrocarbons

from natural gas has largely replaced the old electrolysis process

(world wide this now only accounts for 1% of total H2

production). Now, however, it is no longer conceivable to use

old electrolysis or the steam reforming technology in a hydrogen

economy. Swiss experts are of the opinion that renewable energies

will never meet the requirements of economical hydrogen production.

L. Brown underlined, in presentation

5, how the only reliable and ecological – hence sustainable

- hydrogen production is via nuclear high temperature reactors

(HTR) combined with a high temperature chemical process (the sulphur-iodine

process) This process, developed by General Atomics, was finally

selected amongst 370 H2-generating chemical processes.

The feature of this process is the use of inorganic chemicals

only (Iodine and Sulphur) and water as the feeding material, to

produce H2 and O2. Depending on its chemical

effectiveness losses of iodine have to be compensated for. The

selection of suitable corrosion-resistant vessel and pipe materials

make the equipment expensive.

This High Temperature Water Splitting process

absorbs most of the reactor’s fission heat and has the potential

to achieve up to 70 % efficiency. The total efficiency of the

chain of hydrogen production, distribution and conversion of fuel

cells into power and heat is comparable to that of modern natural

gas burning co-generation or district heating plants. It has the

advantage of zero consumption of fossil resources and does not

emit climate change-inducing carbon dioxide. The fundamental viability

of this water splitting process will be demonstrated by 2010 and

in 2020 an industrial scale engineering demonstration plant on

will be operational.

State-of-the-art HTR technology, its international

development and the time required for further materials research

was covered by presentations 6 and 7. Presentation 8 was dedicated

to cost considerations of the several building blocks needed to

support the hydrogen economy in a small but well-industrialized

country like Switzerland and in a larger industrialised nation

like France.

In presentation 6, K. Foscolos gave

a short overview of recent developments in reactor technologies

and presented in detail HTRs - both existing ones (Generation

IV) and future ones like improved HTRs called “VHTRs.”

The latter will produce fission heat at a level of up to 900°

centigrade. Switzerland is an active member of the GIF, in which

the most important nations contributing to this research co-operate

with each other.

The experts believe that the full potential

of these reactors must be exploited so that they can become the

work horses of a hydrogen economy. Light water reactors will play

a minor role in such a scenario. As far as the availability of

uranium as a main fuel resource is concerned it is concluded that

– in contrast to the declarations made by “anti nukes”

– by using the advanced VHTRs uranium becomes nearly inexhaustible

since uranium can be extracted cost effectively from sea water

by using heat from VHTRs. Such a process makes uranium in sea

water exploitable.

One important step towards the operation of VHTRs

concerns the selection of materials for reactor components, which

must be resistant to very high temperatures. According to W.

Hofelner [in presentation 7] at least 15 years of further

development are required to make VHTRs available on an industrial

scale within 25 years.

F. Werkoff devoted his lecture

[presentation 8] to economic calculations of the investment costs

for the H2 economy and presented helpful formulae.

In addition, he explained the High Temperature Electrolysis (THE)

process working during the vapour phase of water. This new process

has, above all, the potential to compete with the S/I process

but with the advantage that THE can be used with heat sources

like conventional biomass, domestic incinerators and even light

water reactors to produce hydrogen. For France it was calculated

that within the next 45 years 85 % of the French car and truck

fleet could be converted to using H2 fuel cells requiring

16 light water reactors of the type EPR instead of 75 HTRs. When

it comes to using LWRs in a hydrogen economy, the CEA obviously

differs from the HTR-community.

This precise and detailed information lead the

authors of presentation 1 to the conclusion that with respect

to the different building blocks needed to support a hydrogen

economy only two blocks determine the critical path of a solution

tailor-made for Switzerland:

-

cheap, large scale H2 storages based on metal

hydrates

-

suitable, corrosion-resistant materials for VHTRs

The corresponding time span of 15 years would

enable the start-up of a 20 year demonstration project aimed at

achieving a smooth transition from imported natural gas to hydrogen.

Such a project would comprise of the following steps:

-

Installation of stationary fuel cells into

every newly constructed apartment building with more than

10 flats for a period of 20 years

-

Connection of fuel cells to the electricity grid for feeding

generated power into the grid

-

Construction of local H2-gas grid sections

-

Supply of fuel cells first by natural gas and later on by

conventionally produced H2 supplied by tanker lorries

-

Successive construction of H2-storage tanks at

strategic points of the gas grid (according to the progress

with the availability of metal-hydrate storages)

-

Start of the design and construction of one HTR- H2

production plant, comprising of two 600 ME reactor blocks

-

Adaptation of existing gas grid to increase H2-concentration

-

Connect H2-plant to gas grid

-

Increase H2-content of gas grid to 100 %

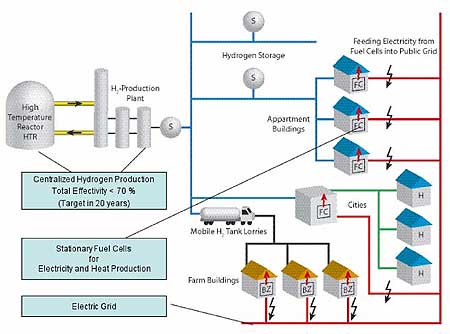

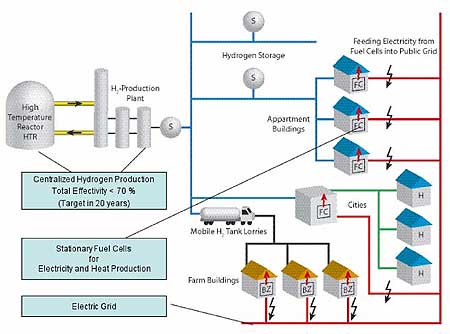

This sequence of steps corresponds to the illustration in Fig.1,

starting with the part on the right hand side (stationary fuel

cells, initial supply of FC by natural gas from public grid then

mobile H2-transportation, installation of H2-storages

and finally realisation of a HTR & H2-generation

plant, lefthand side)

This sequence of steps would:

-

enable Swiss small and medium sized enterprises to be prepared

for switching over to an H2 infrastructure

-

make consumers and suppliers acquainted with use of H2

-

enable reimbursement of fuel cell produced electricity fed

to the grid

-

allow for the correction of any project that shows misleading

results

-

give the utilities time to master the decentralized production

of electricity by the fuel cells

After a successful demonstration of the feasibility

of this small part of a hydrogen economy in Switzerland another

15 years period should be sufficient to extend the hydrogen economy

to cover the whole of Switzerland. The calculation on an investors

level show that within this demonstration project, starting with

conventionally produced H2, total operational cost

of this part of a Swiss Hydrogen Economy is significantly below

the operational cost of the equivalent gas/oil burning for the

apartment houses (gas/oil prices exceed .095 US$/kWh and .0702US$/kWh

respectively). The question raised in the seminar’s title

can now clearly be answered.

Moreover, the reduction of the CO2

emissions by the demonstration project corresponds to 34 % of

consumption of gas and oil fuel used for heating so far. It is

about three times the amount of the energy forecast to be produced

in Switzerland in 2035 by renewable energy. If all Swiss gas and

oil consumption for heat production were to be replaced by hydrogen

Switzerland could contribute fighting climate change and be a

model for other industrial nations to follow. The technologies

exist and are available. In a hydrogen economy the savings obtained

from constant energy prices would be considerable.

Fig. 1 Concept of a Demonstration

Project for replacing fossil fuel by hydrogen and fuel cells to

heat private and public houses (source Nuclear News, September

2001)

References

|

[1] |

Böhnert, A. and M. Nandakumar,

Colenco Power Engineering Baden-CH

Stepwise Entering into the H2-Economy in Switzerland,

the View of an Investor

|

|

[2] |

P. Dietrich, Paul-Scherrer Institute Villigen-CH

Swiss Research Contributions to Building Blocks of H2-Economy

|

|

[3] |

Heyder, B., Kessler, A., Edel, M, EnBW,

Karlsruhe-DE

Experiences with Stationary Fuel Cells for Industrial and

Household Heating

|

|

[4] |

R. Schiffbauer, Linde-PanGas, Switzerland

Industrial H2-Production and Experiences in Operating

H2-Distribution-Pipelines

|

|

[5] |

L. Brown, General Atomics, San Diego,

CA

Large scale Hydrogen Production by HTR: The Sulphur Iodine

Process (engl.)

|

|

[6] |

K. Foskolos, Paul-Scherrer Institute Villigen-CH

High Temperature Reactors for H2 -Production

|

|

[7] |

W. Hoffelner, Paul-Scherrer Institute

Villigen-CH

Technological Evolution and Materials for HTR and VHTR

|

|

[8] |

F. Werkoff, Centre du CEA –Saclay,

Paris

Hydrogen from helium cooled reactors: can we compare the

thermochemical Sulphur/Iodine cycle and the High Temperature

Electrolysis? (engl.) |

|