ICEM Conference focuses on training and educating

tomorrow’s nuclear sepcialists

The BNES YGN was recently given the chance to present

at the 11th International Conference on Environmental

Remediation and Radioactiove Waste Management (ICEM 07), which

was held,

in Bruges, from 2-6 September. The YGN were invited to host 2

sessions, the first relating to workforce issues and training

programmes and the second a panel session where we invited Jean

Llewellyn, Project Director for the National Skills Academy for

Nuclear, to join us and lead the debate about challenges facing

the YGN. Both sessions were hosted by our YGN Chair Neil Crewdson

and Vice Chair Linda McLean. The sessions were very positive,

with all speakers leading a debate into the difficulties that

we are facing and offering their perspectives on how we are responding

to the change in demand for skills as we engage the current nuclear

renaissance.

The first presentation was by George Reeves.

He discussed the first 2 years in operation of DERC – a

centre for decommissioning and environmental remediation in the

highlands of Scotland and the problems he faces securing funding

and places for future applicants. Sarah Greenwood from RM Consultants

next explained how she has developed a programme to spot talent

in graduates and support them through their career development

until they become qualified and successful consultants. The Dalton

Institute was represented by Warren Richards who discussed how

industry, government and research councils are taking steps to

reverse the 20 year trend of underinvestment that has led to

the current skills shortage. He then focused on several programmes

such as the development of the Dalton Institute and the national

laboratory. Ogla Batyukhnova of Russia added an international

dimension to the session by telling us about the last 10 years

of the Moscow SIA Radon international education training centre

and how they use several methods, including socio-psychological

aspects, when assessing the efficiency of their training programmes

aimed at ensuring that they can continuously improve training

methods.

My presentation focused on graduates and how

they are being developed in the UK. It focused on the highs and

lows of graduate training and how the YGN and the NDA are focusing

on improving graduate programmes to recruit and retain the best

graduates into the industry.

The panel session kicked off with an introduction

from Jean Llewellyn, which lead to a lively debate on the challenges

the industry is facing due to the shortage of skills. The audience

quickly joined in and Richard Mrowicki from the NDA answered

some difficult questions relating to the NDA programme and how

it was effecting the development and training programmes offered

by some companies. Over all, the event was very forward-looking.

The key messages that emerged from the conference were that we

must work together to address the skills shortage and ensure

that the nuclear industry is made more attractive for graduates

and their career development.

For more information on the conference consult the ICEM

07 web

site at: www.icemconf.com

French Technical Tour

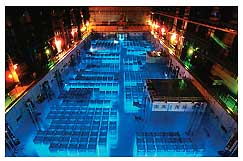

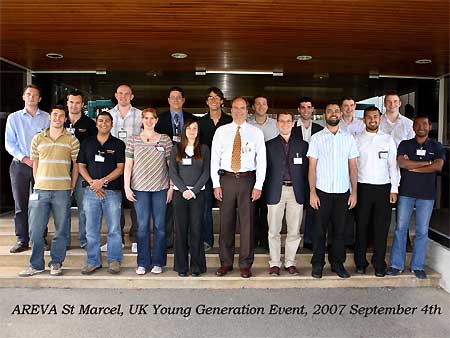

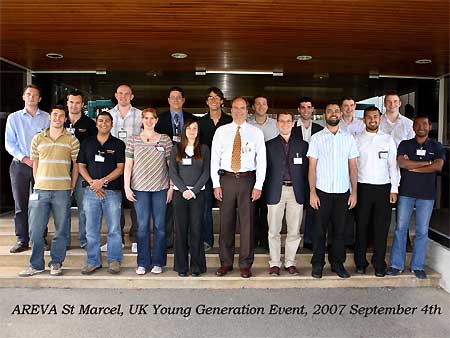

Whilst the ICEM conference was going on a technical tour of

France was also taking place. The tour was organised by Ben Salisbury

of British Energy and the BNES YGN and hosted by AREVA and ENS.

The tour was attended by 17 BNES YGN members

representing a variety of nuclear backgrounds. Starting in Marcoule,

in the south of France, the tour travelled north to Flamanville,

in Normandy, following the closed nuclear fuel cycle that Areva

NC operates. This incorporated the reprocessing and recycling

of plutonium and uranium for use in “MOX” fuel, as

well as the segregation, treatment and disposal of used fuel

elements and radioactive waste. The tour also included visits

to the steel forge and metalworking plants which produce plant

components. Finally an operating light water reactor was visited

along with the building site of one of the world’s two

new European pressurized reactors (EPRs).

The following is an extract from the full visit report, which

can be found on the YGN website.

‘On Monday the tour started in Marcoule, Gard Region where

we visited the Phénix, France’s second prototype

Fast Neutron Reactor (FNR). The reactor is a research facility

which can be configured to “breed” plutonium from

fission in uranium 238, thereby increasing the amount of energy

produced from natural uranium by 50%. Alternatively, the reactor

can be used to “burn” radioactive waste and transmute

long-lived fission products and actinides into stable elements

or radioactive products with reduced half-lives. This process,

if extended to a commercial scale, could reduce the nuclear waste

legacy for future generations.

We also visited the Melox plant, which was on

the same site, this plant takes plutonium and uranium oxide from

Areva’s facilities at La Hague. These materials are mixed

to the correct enrichment level for a particular fuel assembly.

The theme for Tuesday’s

visit was the construction of the major steel assemblies

used in nuclear

power plants. The first location we visited was the Creusot

forge plant belonging to the Sfar Steel Group. This forge

is capable of producing very large forged steel components,

some of them weighing up to 360 tons. During the tour a 150

ton ingot of steel was lifted out of one of the gas furnaces

glowing red, placed into the 7500 ton press and had a 10

ton section sliced off. This activity made quite an impression

on everyone.

|

|

Located deep in rural south-eastern France is the Andra waste

disposal repository, final destination for 90% of Frances radioactive

waste, was the destination on Wednesday. This site was especially

chosen on account of the geological make-up of the environment.

The intermediate and low-level waste (ILW & LLW) that is

handled and stored at the facility is not just put into drums;

complete pressure vessel heads are put in place. The group also

visited a second site which handles very low-level waste (VLLW)

and learned about the differences between British and French

disposal methods.

On Thursday, the tour party set off for La Hague, which

specialises in the reprocessing of nuclear fuel from

domestic and overseas clients. Spent fuel is delivered

in large reinforced steel containers and stored in La Hague’s fuel

pond for 3 years. The reprocessing facility is vast, covering some 300 hectares

and employing

|

|

around 6,000 people it extends underground and all of the processing

is remotely controlled to limit employee exposure.

The final stop on the tour was Flamanville, with its two EDF

PWR reactors with a capacity of 1300MW each. These stations,

although impressive, were not as interesting as the construction

site next to them. In this site the foundations of the new Flamanville

3 EPR station have been laid. However, at this early stage all

that could be seen were some basement sections and the bottom

of the containment area. The site physically looks larger than

the sister stations. This is intentional in order to provide

4 levels of system redundancy, increased lay down areas that

enable easier maintenance and an increased power output of 1600MW.

From the outset the EPR design is MOX adapted and builds upon

the operating and construction experience obtained from the 93

other PWRs that Areva has built.

Standing there and looking at the framework

of the new EPR under construction you were struck by the realisation

that the future was unfolding before you. A closed fuel cycle

with minimised volumes and toxicities of radioactive waste coupled

to effective reprocessing and recycling of uranium and plutonium

to reduce demand on world resources. And all this supporting

a technology that is proven, safe, reproducible, low carbon,

cost effective and currently supplying 80% of Frances energy

needs. It certainly looks like a good model to work from.

Steven Wootten (British Energy)

|