The Centre for Technology Transfer’s new patented technology and equipment for the reprocessing of radwaste

The Centre for Technological Transfer Ltd. is a new Bulgarian company that specialises in the international transfer of innovative technologies and know-how. Its main mission is to collaborate with leading companies in the nuclear energy field to implement new innovative and scientific solutions that not only have a commercial goal, but also provide a definite benefit to society.

We propose an effective new solution for managing the radwaste that results from the operation of light water reactors (PWR, WWER). By applying our patented technology and equipment we can reduce the volume of output radwaste through recycling, as 90% of the existing borates are reprocessed to produce an industrial non-radioactive product and reagents.

We have accumulated data relating to the reprocessing of real liquid radwaste from the VVER 1000 reactor at Kozloduy NPP. We also have at our disposal information on how to operate a semi-industrial (prototypic) installation, including that related to operational modes, the dose loading of personnel, the radiation state of the devices and other data necessary for normal and non-accident related servicing.

The method used for radwaste reprocessing includes the separated collection of the radioactive waste water, separated concentration and subsequent mixing. This is characterised by mixing radwaste containing boric acid (between 35 and 200 g/l) with radwaste of a summary salt concentration of between 400 and 500 g/l that doesn’t contain boric acid. During this process non-radioactive salts are removed. The concentration of borates at a level of between 20 and 25 g/l is reached in the radioactive waste concentrate, which in turn is mixed with a solution of alkaline metals in order to produce insoluble non-radioactive borates of alkaline metals and between 2 and 4 g/l of liquid radwaste containing boric acid.

The method and the equipment used for liquid radwaste reprocessing allows the collection, without any harm caused to the environment, of borax, calcium and magnesium borates, solutions of boric acid and basic sodium. These products are valuable because they can be reused. The method can also be used to collect and store radwaste, while allowing for the continuing harvesting of salts, which doesn’t require control.

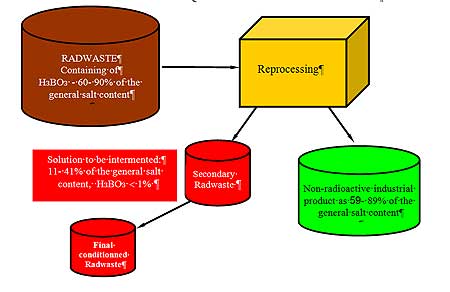

GENERAL SCHEME FOR LIQUID RADWASTE REPROCESSING

Remark: The volume reducing depends on the percentage content of borates in the output radwaste – a higher reducing coefficient of the secondary radwaste is achieved at a higher level of borates concentration.

On the base of available data from tests carried out one can conclude the following:

During the tests carried out on the liquid phase of the radwaste, 6,883 liters of a solution with a salt concentration of 250-270g/l were reprocessed, from which НзВОз (35 g/l), NOз SO4 Na, K, lubricants, and 120 kg of non-radioactive salts were removed. During tests carried out the solid phase of the radwaste, 103 kg from the operational radwaste storage (BKO) tanks were reprocessed and 78 kg of non-radioactive salts were removed. The aim of the tests was to obtain a non-radioactive salt, which explains why the tests were stopped when a residual concentration of 10-15 g/l was achieved for the liquid phase and a level of 25-30 g/l was achieved for the solid phase.

Examples:

The reprocessing of 100t of radwaste containing 60-90t boric acid - direct reprocessing through cementation carried out at Kozloduy NPP: 1200-1800 m3 liquid radwaste at concentration level of 50 g/l НзВОз will be reprocessed through cementation and will take up 3,500 – 5,100 m3 of radwaste storage space.

Reprocessing through implementation of the said technology and consecutive cementation as carried out under normal conditions at Kozloduy NPP: By applying our technology to the same volume of above-mentioned liquid radwaste, 59 – 89 t of pure borates (containing a maximum of 50 Bq/l radioactive caesium) will be obtained, and 12.5 - 50 m3 of liquid radwaste with a concentration of 5 g/l of НзВОз will undergo cementation. This will take up 40 - 150 m3 of radwaste storage space. The concentration process is not influenced by the content of radionuclides. The higher the concentration of radionuclides, the higher the purification coefficient.

The reprocessing of 100 m3 radwaste containing 75-95 g/l boric acid at a general salt concentration level of 100g/l - direct reprocessing through cementation for PWR radwaste: 150 - 190 m3 liquid radwaste at a concentration level of 50 g/l НзВОз will be reprocessed through cementation. The result will take up 270 – 350 m3 of radwaste storage space.

Reprocessing through implementation of the said technology and consecutive cementation in accordance with the normal conditions governing PWR radwaste:

By applying our technology to the same volume of above-mentioned liquid radwaste, 7.45 - 9.49 t pure borates (containing maximum of 50 Bq/l radioactive Cesium) will be obtained and 1 - 5 m3 of liquid radwaste with a 5 g/l concentration level of НзВОз will undergo cementation. This will take up 1.8 - 9 m3 of radwaste storage space. The concentration process is not influenced by the content of radionuclides. The higher the concentration of radionuclides, the higher the purification coefficient.

The result of applying the said technology:

-

Besides the economic effect, which is also expressed through very low initial costs, there is a positive influence on the radiation safety during the storage of radwaste obtained through cementation, because the quality of the cement matrix is thus improved.

-

The applied technology is not influenced by the initial content of radionuclides and the presence of insoluble sediments, complex-formers, surface-active materials, organic products, soaps, oxidants, reductors, desactivating solutions and other impurities.

For further information about this patented technology and the installations required to apply it, please contact:

Contacts:

Dr. Dimitar Popov

e-mail: dimitar@kth.se

tel. +359 884 563 836

Dipl. Chem.Eng. Krasimir Filipov

tel/fax: +359 2 846 6507

e-mail: ctt_bg@abv.bg

tel: +359 895 742 687; +359 899 800 445

Dipl. Eng. Vladimir Vladimirov

tel.+359 899 800 446

ID’s of our patent:

BG65037 (Bulgaria)

US 7323613 (USA)

JP4495458 (Japan)

ZL02822276.8 (China)

(in EU the registration is being performed)

Here is the patent publication in USA Here is the patent publication in USA

|