Technology research - the SUSEN project and the nuclear fuel cycle (JPC)

The NRI Group, which is a member of the Czech Nuclear Society, is currently carrying out the largest nuclear research investment project in the Czech Republic. It represents a significant milestone for nuclear R&D in the Czech Republic, a country with almost 60 years of nuclear history. The Czech Nuclear Society (CNS) would like to present you here its Nuclear Fuel Cycle research programme, which is directed by Mr. Kovarik, a member of the CNS board.

The SUSEN (Sustainable Energy) Project is being carried out at two regional R&D centres. The total budget of the project is approximately €95 million. It focuses mainly on extending the life cycle of existing R&D facilities and on the development of new technologies for supporting current reactors and future GENIV reactors. SUSEN is divided into 4 research programmes: Technological Experimental Circuits (TEO), Structural and System Diagnostics (SSD), Nuclear Fuel Cycle (JPC) and Material Research (MAT). The project is being undertaken at two regional centres - in Pislen (at the West Bohemia University) and the headquarters of the Rez Research Centre.

The Nuclear fuel cycle (JPC) research programme focuses on R&D related in particular to the back end of the nuclear fuel cycle, more specifically low and intermediate level waste (RAW) management, deep geological disposal and the reprocessing of spent nuclear fuel. In the following report the main technologies that are developed under the SUSEN Project on the Nuclear Fuel Cycle are outlined. More information about the project can be found at: www.susen2020.cz.

FERDA2 technology line

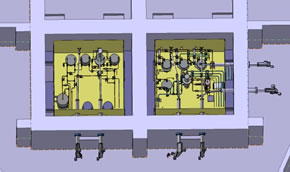

The FERDA2 (Fluoride Research and Experimental Development Assembly) technology line is a research facility which will be used for carrying out the separation of radionuclides from irradiated uranium oxide using the fluoride volatility method. FERDA2 will be situated in the hot cells. It is designed to perform experiments with irradiated uranium powder. It is a prototype device for demonstrating the fluoride volatility method for different spent fuels from currently operating and/or GENIV reactors. To some extent, the FERDA2 technology line follows on from the RENATA, FREGATE-2 and FERDA 1 research lines, which were designed and put in operation at UJV Rez in cooperation with the former Soviet Union between 1975 and 1987. The basic design of FERDA 2 has been finalised and the technological line has moved on to the manufacturing and building phase. The deadline for completion of construction, commissioning and final handover is December 2015.

Fig. 1 - FERDA2 technology line - view inside the hot cells

Experimental loop for working with molten salt

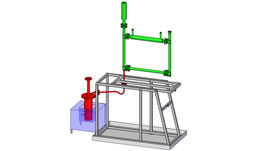

The objective of this device is to study the behaviour of molten fluoride salts, methods of preparing and handling molten salts in various operating modes, performing long-term corrosion tests and tests of various types of seals in flanged joints. The construction of the loop should allow the simple replacement of tested parts within a modular system framework. The device should also serve to verify the measurement systems, to develop measuring sensors and measuring technology for molten salt reactors, to study the dynamics of systems with molted salts and to study issues related to their stability and safety. Last but not least, the loop demonstrates the transferal of thermal energy flow.

Fig. 2 – Experimental loop for working with molten salt

MSO technology line

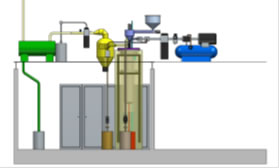

The MSO (molten salts oxidation) technology line is an experimental semi-pilot plant used for carrying out the non-flame oxidation of solid and liquid low-level and medium-level toxic wastes in molten salts. The research objective here is to assess the real operational applicability of molten salts for the effective destruction of the above-mentioned types of waste, both in terms of environmental technology and economic suitability. The MSO technology line will be a modular system and, according to needs, will allow for the extension or replacement of some of the technology and support systems (eg, measurement and control). Currently, the tendering procedure for the supply of this device is open and the deadline for completion of construction, commissioning and final handover is December 2015.

Fig.3 –MSO technology line

Technology line for the processing of liquid radioactive and hazardous waste

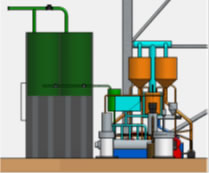

This device is a modular system simulating certain methods used for processing liquid radioactive waste and secondary waste at nuclear power plants (evaporation, in-drum drying, bituminization). The purpose of the device is to optimize this process, to study other processes that might lead to the minimization of liquid and semi-liquid radioactive waste, to develop new matrices for the solidification of concentrates, to develop methods for the fixing of saturated and non-saturated ion exchangers, etc. The device will also be used for developing prototype modules and various design elements that will be suitable for innovating existing facilities, thereby increasing their performance and efficiency, reducing energy consumption and extending their service life. At present, the tendering procedure for the supply of this device is open and the deadline for completion of construction, commissioning and final handover is July 2015.

Fig.3 – Technology line for the disposal of liquid radioactive and hazardous waste

Cold crucible technology

An induction furnace with a cold crucible is an instrument that is used for the high-frequency induction melting of materials and the investigation of high-temperature melts. The main advantages of this method are the non-pollution of the melt material and the possibility of reaching and maintaining the melt at a high temperature (more than 3000°C). The device will be used for materials research (phase diagrams) and especialy for research into the high temperature synthesis of functional materials, for the simulation and monitoring of physico-chemical properties of oxide mixture melts based on CORIUM and for the modelling of severe accidents in nuclear power reactors. Last but not least, this device will be used for vitrifying radioactive waste. At the moment, the tendering procedure for the supply of this device is open and the deadline for completion of construction, commissioning and final handover is December 2014.

Fig.3 – Technology line for the disposal of liquid radioactive and hazardous waste

The laboratory will house two induction systems equipped with a cold crucible. The first installation will have an generation output of up to 160kW and the second one will have an generation output of up to 300kW.

Jana Dymáčková and Petr Kovařík,

Rez Research Centre, plc.

|