Periodic Safety Review NPP Borssele reduced TCDF

by a factor of 4.

Introduction

Borssele is a two-loop PWR built by Siemens KWU,

that became operational in 1973. It is operated by the Dutch utility

EPZ, which over the years has invested regularly in safety and

efficiency. After its first PSR a plant modernisation programme

of around 250 million Euros has been implemented in 1997 during

a five-month outage. Highlights included the back fitting of new

primary safety valves, new steam and feed water lines, a new control

room, an emergency control room, new emergency diesel generators

with higher capacity and a reserve ultimate heat sink.

In 2004 EPZ has decided to improve the plant’s

balance of plant to a gross capacity of 510 MWe (see e-news issue

15, winter January 2007). This was carried out by Siemens during

the 2006 outage.

In the same outage also the majority of measures

were implemented that followed from the second PSR. These improvements

have resulted in another significant gain in nuclear safety (see

figure 1).

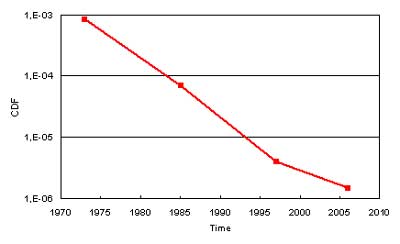

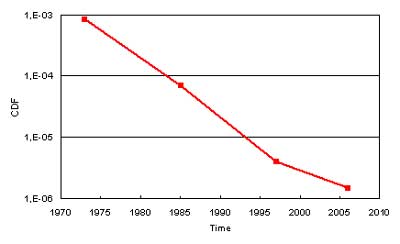

Figure 1. Changes in total core damage frequency

as a result of safety improvements.

This paper reports on the process of the latest

periodic review, as well as on examples of implemented measures.

The associated gains, in terms of nuclear safety, are seen as

the first priority for EPZ. At the same time these gains contribute

to our goal of staying in the top of the safest nuclear power

plants in the western world.

Periodic safety review

The operating license of the Borssele power plant

stipulates that EPZ should conduct and report a periodic safety

review every 10 years. This PSR is extensive and analyses developments

in technology and regulations with respect to the current licensing

base. The periodic safety reviews cover both design and operation,

with technological-, organisational-, personnel- and administrative

aspects.

The most recent PSR covers the period 1993 –

2002 and consists of an evaluation-, a conceptual- and an implementation

phase. An important result of the evaluation phase was that Borssele

is operated safely, in compliance with (inter)national regulations

and current state-of-the art technology. In addition, several

areas for further improvement and optimisation have been identified.

The improvements have been selected, amongst others, for their

impact on the total core damage frequency contribution (TCDF,

PSA Level 1) and on individual risk contribution (PSA Level 3).

This was calculated with the full scope, plant-specific living

probabilistic safety assessment model. In figure 1 the integrated

effect of these improvements on the total CDF is given. It shows

that the most recent periodic safety review has resulted in another

significant gain, despite the 1985 and 1997 back fitting projects

which already reduced the original total CDF number significantly.

An important decision has been to increase the so-called mission

time in the PSA from 24 hours to 72 hours. This has allowed us

to identify areas of improvement beyond the original 24 hours

after the occurrence of an event. It has turned out that for some

rare external events a significant safety improvement could be

achieved.

Evaluation phase (1999 – 2003)

The evaluation of subjects for improvement started in 1999 by

gathering information from different sources, such as:

-

Input from personnel (listening to own organisation)

-

Assessing new and upcoming regulations (national, KTA and

IAEA)

-

Information from aging programmes (conceptual and physical)

-

Probabilistic Safety Analyses (In house living PSA model,

as well as know-how of commercial companies in the field of

PSA)

Over more than 1200 issues were gathered and

clustered in 26 basic reports. After a first evaluation 176 issues

of potential improvement were selected, based on know-how and

PSA data.

Conceptual phase (2003 – 2005)

The potential improvements were further analysed

during the conceptual phase, and measures were formulated in order

to obtain the improvement. An estimation of costs was made together

with the expected benefits, which were selected on expected gains

in nuclear safety and based on:

-

Probabilistic information.

Impact on the total core damage frequency (CDF) and the individual

risk were calculated with a plant-specific living probabilistic

safety assessment model.

-

Deterministic information.

Upcoming regulations and defence-in-depth approaches (failures,

availability, reliability,..) was analysed.

-

Radiation protection gain.

Collective, individual and environmental doses were calculated.

The issues for improvement were split into Technical

(design) measures and OPA measures (organisational, personnel

and administrative measures). All measures were subject to a cost/benefit

analysis, and the end result has been agreed upon by the regulator

in June 2005.

Implementation phase (2005 – 2007)

The modifications resulting from the technical

measures were conducted by a separate project organisation. It

covered around 35 measures of which 20 measures were conducted

by own personnel. The remaining 15 measures were carried out by

the consortium Belgatom – GTI on a design & construct

basis. Within this consortium Belgatom was responsible for the

project management, the nuclear engineering and the final testing.

Detail engineering, purchasing and construction was carried out

by GTI.

The engineering process and (safety) evaluation

by personnel took place in 2005 and first half of 2006. Some of

the measures required a change in the operating license. This

was honoured in the beginning of 2006. Therefore, construction

could start in the second half of 2006, and was concentrated in

the outage of 2006. In 2007 some smaller constructions are finalized

and documentation is completed. In the following paragraphs some

examples are given, showing the diversity of the implemented measures.

Figure 2. Remotely opened explosion hatches.

Defence in depth measures.

Several defence in depth measures were formulated

that cover different lines of defence, i.e. from prevention of

system failures to extending the design basis of the plant. Examples

of these measures are the installation of new improved seals of

the low pressure safety injection pumps, an additional feeding

possibility of the back-up decay heat removal system with a fire

pump, installation of an additional pump in the cooling circuit

for the irradiated fuel storage pond, and an additional pump for

the emergency residual heat removal system.

Furthermore, the installation of a connection

between the two emergency grids (6kV – 400 V) and extending

battery power have been carried out. The power supply of the reactor

protection system is extra secured and the dependence of the external

grid has been further diminished, resulting in a significant gain

in CDF.

As a last example, remotely opened explosion

hatches have been installed (see figure 2). Between the operating-

and the innercontainment section of the reactor building there

are explosion hatches, which are designed to burst open in case

of accidental pressure build-up, so as to limit damage to the

innercontainment. In case of a very small LOCA with hydrogen buildup,

the explosion hatches at top and bottom of the steam generator

sections can now be opened remotely from the control room. In

this way an air flow is forced by means of a chimney effect. The

hydrogen will mix and reach the passive recombinators at the different

positions in the reactor building.

Figure 3. Air intake of bunkered diesels.

Assessing risks from external events.

In a periodic safety review also off-site events

are assessed that could influence the plant’s safety. Increased

traffic of LPG tankers on our river have led to installation of

igniters for external flammable clouds. More severe storms and

sea level increase, due to a possible climate change, has led

to an even more conservative design level of external flooding.

The air intakes of the bunkered diesels were placed higher up

with an external structure attached to the bunkered building (see

figure 3). Because of the safety function, the pipework is earthquake-proof,

blast-proof and on different sides of the building to reduce common

mode failure.

Also a crashtender (see figure 4) was acquired

to be able to fight kerosene fires that would challenge vital

buildings.

Figure 4. Crashtender for fighting kerosene fires.

|