SCK•CEN (the Belgian Nuclear Research Centre)

is a candidate for hosting a European fast spectrum experimental

facility for demonstrating efficient transmutation and associated

technologies using a system that works in sub-critical and/or

critical mode. With this in mind, SCK•CEN started, in 1998,

designing the MYRRHA facility as an accelerator driven system

(ADS) with the following objectives:

-

To demonstrate ADS technology, full-scale,

within the framework of research into the transmutation of

high-level waste

-

To serve as a flexible fast spectrum irradiation facility

for testing materials and innovative fuels for ADS and

GEN IV systems

and fusion reactors

-

To contribute to the technological demonstration of the

GEN IV Lead Fast Reactor

-

To perform fundamental and applied physics research

making use of SCK.CEN’s high power proton accelerator

MYRRHA should be operational in 2020 and is designed as an open

user facility for the international research community in the

fields of physical science, waste transmutation, nuclear engineering,

radioisotope research and production, as well as for material

and nuclear fuel science.

Since the start of the FP6 EUROTRANS integrated

project launched by the European Commission in 2005, MYRRHA has

served as a basis for a small-scale, short-term experimental

facility demonstrating the technical feasibility of “Transmutation

in an Accelerator Driven System (XT-ADS)” machine. The

main parameters and characteristics of the MYRRHA facility are

as follows:

-

The MYRRHA accelerator is based on LINAC technology

in order to fully demonstrate the industrial scale ADS and

to meet the very demanding conditions in terms of beam reliability

(reduction of the number of beam trips longer than 1 second,

up to a maximum of 10 to 20 trips per year)

-

The windowless spallation target concept

of MYRRHA has progressed in terms of design and demonstration

on the

basis of an important

international experimental programme complemented by an

international Computational Fluid Dynamics (CFD) effort

for the free surface

treatment. The evidence of the feasibility of the proposed

design is no longer questioned with respect to its fundamental

aspect,

but some issues still remain open with regards to its fine

tuning and advanced design, which will be addressed over

the next 3

years

-

The core maximum sub-criticality level

of keff ~ 0.95 assures a comfortable margin

for safe operation. The

total power

ranges from between 50 to 80 MWth (depending on the core

loading and

the experimental rigs inserted). The total neutron flux

levels (1 1015 to 5 1015 n/cm².s)

achieved in large irradiation volumes in the core (about

20.000 cm³ in total) enable

very high performance testing conditions

-

The MYRRHA fuel design is based on fast

reactor (FR) MOX fuel technology (30% Pu contents) with T91

ferritic-martensitic

steel

for the cladding and for the fuel assembly wrapper.

The inlet

temperature is 300°C and the outlet temperature is 380°C.

The targeted fuel residence time is 3 years. Nevertheless,

the MYRRHA core is designed to accept minor actinide based

fuel assemblies

whenever these are made available

-

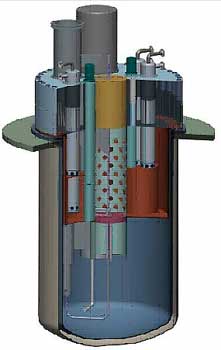

The primary system of the MYRRHA facility

is based on a pool design cooled with Pb-Bi as a primary

coolant (see figure 1) and boiling water as a secondary fluid.

The heat exchangers and primary pumps are immersed in the

reactor vessel in dedicated casings. Interim fuel storage

inside the primary vessel can host the used fuel for decay

heat before transfer out of the vessel

-

The MYRRHA building was conceived from

the very beginning to take into account remote handling and

robotics based

operation and maintenance within a controlled atmosphere,

limiting

the LBE contamination by O2 trapping. The

remote handling for both out-of-vessel and in-vessel

operation and

maintenance

was developed using existing and demonstrated technology

in the Joint European Torus (JET) fusion facility.

Figure

1: Vertical cut of the MYRRHA/XT-ADS sub-critical reactor

In April 2008, SCK•CEN, together with

its European partners, answered a FP7 call for establishing a

Centralised Design Team for a Fast Spectrum Transmutation Experimental

Facility to be able to work in sub-critical and/or critical mode.

Within this framework and starting in 2009, the MYRRHA/XT-ADS

design will be updated to allow for critical mode operation.

The partners involved are the following research organisations:

CEA (FR), CNRS (FR), FZK (DE), FZD (DE), CIEMAT (ES), ENEA (IT),

NRG (NL) and ITN (PT). From the nuclear industry the partners

involved are: Ansaldo Nucleare (IT), Del Fungo di Giera Energia

S.p.A. (IT), AREVA NP S.A.S (FR), Empresarios Agrupados (ES),

SENER (ES), ADEX (ES), OTL (UK) and CRS4 (IT). Also involved

are two universities: UPM (Spain) and UPV (Spain). Since the

MYRRHA project is moving to an industrialisation phase, the partners

leading the major work-packages are from the nuclear industry.

The MYRRHA project (technical description and

business plan) has been submitted to the Belgian minister of

energy with a request for financial support for a significant

part of the cost of the initial engineering phase of MYRRHA and

for its final realisation at a later stage. As a result, in the

governmental agreement signed by the new "Leterme I" Belgian

federal government, which was formed in March 2008, support for

the MYRRHA project is regarded as an international research infrastructure

that serves research programmes looking at the reduction of long-lived

waste and the production of radio-isotopes for medical applications.

Currently, SCK•CEN is in discussion with the Belgian government

to set the specific requirements and conditions of this support.

A detailed business plan for MYRRHA exists (MYRRHA

Project – Business Plan 2007, SCK•CEN Report, reference

ANS/HAA/DDB/3900 B043000/85/07-17, April 2007). From the plan

it is possible to identify a total investment cost, expressed

in 2007 values and spread over 12 years, of ~700 M€. The

operational costs are estimated to be 38 M€ per year.

The 2007 R&D programme for MYRRHA at SCK•CEN

features various highlights. Here are some of them:

-

The primary and secondary system component

configurations were further elaborated and optimized. The

system components were calculated in detail. The diaphragm

separating

the hot and cold lead-bismuth coolant in the reactor vessel

was largely simplified. This new configuration of vessel

components

resulted in an enhanced capacity for natural circulation

in emergency situations. The specifications for the experimental

devices (in

pile sections) were formulated according to the MYRHA/XT-ADS

objectives and adapted to the actual core and core support

structure design

-

The neutronic calculations for MYRRHA/XT-ADS

were mainly focused on two topics. Firstly, the estimation

of the neutron

induced

damage (dpa) on the core barrel and top grid. This led

to a recommendation to increase the core by two extra rows,

thereby increasing the

space between the last row of fuel assemblies and the core

barrel. Secondly, calculations were performed to estimate

the neutron

fluxes in the eight in-pile-positions. In addition, scoping

calculations for a burn-up cycle and reshuffling scheme

were made

-

The issues of vacuum and lead-bismuth conditioning

for the windowless spallation target were addressed through

dedicated

experiments, including experiments simulating the proton

beam surface heating with an electron beam (WebExpIr).

It was shown

that the high intensity heating has no distortive effect

on the target surface flow and that the vacuum conditions

remain well

within the operational limits

-

One of the fundamental design options is

that all maintenance and in-service inspection and repair

duties in MYRRHA

will be performed by remote handling. In view of this,

a first

version

of the Remote Handling Design Catalogue (RHDC) for

MYRRHA/XT-ADS was released. This RHDC provides information

and guidance

to engineers, CAD designers and technicians with a

view to ensuring

that the MYRRHA/XT-ADS machine, as well as its remote

maintenance system, is designed in a way that is fully

compatible with

the remote handling requirements. The catalogue contents

were finalised

in cooperation with Oxford Technologies, taking advantage

of their experience with the fully remote maintenance

of the EFDA-JET

Fusion Tokamak project

-

Significant progress was made with the

development of ultrasonic techniques for visualisation in

liquid

lead-bismuth

under gamma

radiation. An acoustic computer model was developed

and validated on a mock-up in water. The research

to improve

the diffusion

bonding process to obtain a reliable ultrasonic transducer

for application in LBE is ongoing

-

Material irradiations in stagnant lead-bismuth

in the BR2 reactor have been performed to investigate

the behaviour

of the fuel

cladding and structural materials, considered for

MYRRHA/XT-ADS,

in representative conditions. The samples are being

analysed during the course of 2008

-

As a first step towards the development

of MYRRHA the GUINEVERE project was launched and formally

accepted by the Governing

Council of IP-EUROTRANS, in December 2006. GUINEVERE

is a zero-power mock-up of the MYRRHA/XT-ADS

with, as

its

main

objectives,

the

qualification of the sub-criticality monitoring

techniques and its role as a validation model

for the core neutronic

design. GUINEVERE should provide answers to these

questions by 2009-2010.

To achieve this goal, the zero-power critical

facility VENUS facility at SCK•CEN is being adapted to a zero-power

lead fast reactor and coupled to a modified GENEPI deuteron

accelerator

delivering 14 MeV neutrons by bombarding deuterons on a tritium-target

-

An important milestone reached was the

delivery of CEA fuel for GUINEVERE to SCK•CEN, in October and November

2007. Also a derogation to the standard licensing procedures

was

requested in November 2007. This request was approved by

the Minister of

Internal Affairs, in March 2008. The construction permit

has been received in April 2008. The first phase of the licensing

procedure was successfully completed in May 2008.

-

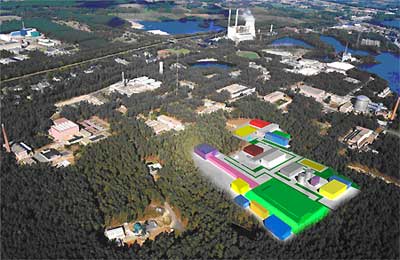

A full plant layout of the MYRRHA complex

has been drawn up on the SCK•CEN technical site at Mol, see figure

2

Figure 2: MYRRHA Plant layout on the SCK•CEN

technical site at Mol (BE)

Contacts:

Hamid Aït Abderrahim (hamid.ait.abderrahim@sckcen.be)

Peter Baeten (peter.baeten@sckcen.be)

Didier De Bruyn (didier.de.bruyn@sckcen.be)

myrrha@sckcen.be

www.sckcen.be/myrrha

|