2006 International Congress on Advances in

Nuclear Power Plants

Embedded International Topical Meeting at the 2006 ANS Annual

Meeting

ICAPP '06 • June 4-8, 2006 • Reno, NV • Reno

Hilton

University of Florida

Dryout of BWR Fuel Elements

Frigyes Reisch Nuclear Power Safety, KTH Royal

Institute of Technology, Stockholm, Sweden

Phone/fax +46 8

7202365

Frigyes@safety.sci.kth.se

1. INTRODUCTION

The surface temperature of the fuel limits the power production

of nuclear reactors. Intense high temperatures can damage

the fuel cladding and cause a radioactive release and even

provoke in-vessel accident resulting in particulate debris

bed, or

core melt down. Therefore, identifying the uppermost permitted

surface temperature in a Light Water Reactor (LWR) is of

great importance. The experiments described here define

the maximum permissible power production of Boiling Water

Reactors (BWR) fuel element without the risk of burnout.

As witnessed by a great number of publications, the search

is going on for reliable criteria to assure the safety

of the fuel. Here one such criteria is analysed. Normally

the

fuel surface is effectively cooled by boiling

water.

However,

when

the heat flux exceeds a critical value the heat transfer

from the fuel surface into the coolant deteriorates, with

the result that a drastically increased fuel surface temperature

occurs. Excessive fuel temperature can be caused by overpower

or reduced coolant flow. At neutronics and thermal-hydraulic

power oscillations when the duration of the power peaks

are very short, temporary high temperature can occur without

causing fuel failures as normal cooling can quickly recover.

To avoid excessive fuel temperature, the knowledge of the

onset of the overheating phenomena is absolutely necessary,

both at the design stage and during the safe operation

of

a reactor. There are complex correlations especially developed

for specific fuel bundle designs. These correlations contains

surface power, mass flow, system pressure and other parameters.

While analyzing the test results it was recognised that

a single parameter, the void, characterises the onset

of the overheating phenomena in a wide range of pressure

and

flow conditions. These results were attained from the experimental

loop especially developed to study the dryout of BWR fuel

elements.

2. MECHANISMS OF CRITICAL HEAT FLUX

Normally the fuel surface is effectively cooled by boiling

water. However, if the heat flux exceeds a critical value

the heat transfer from the fuel surface into the coolant

that deteriorats, with the result a drastically increased

fuel surface temperature occurs. The mechanisms of critical

heat flux are:

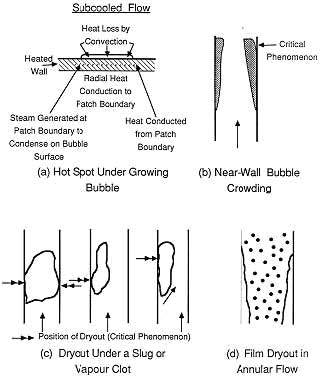

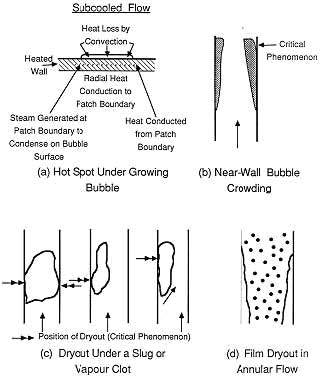

a) Formation of hot spots under a growing bubble. Here when

a bubble grows at the heated wall a dry patch forms underneath

the bubble as the micro-layer of liquid under the bubble

evaporates. In this dry zone, the wall temperature rises

due to the deterioration in heat transfer.

b) Near-wall bubble crowding and inhibition of vapor release.

Here a “bubble boundary layer” builds up on

the surface and vapor generated by boiling on the surface

must

escape through this boundary layer. When the boundary layer

becomes too crowded with bubbles, vapor escape is impossible

and liquid cannot penetrate to the heated wall and cool

it, the surface becomes dry and overheat gives rise to

burnout.

c) Dryout under a slug or vapor clot. In plug or slug flow,

the thin film surrounding the large bubble may dry out giving

rise to localized overheating and hence burnout. Alternatively,

a stationary vapor slug may be formed on the wall with a

thin film of liquid separating it from the wall, in this

case, localized drying out of this film gives rise to overheating

and burn out.

d) Film dryout in annular flow

Figure 1. Critical Heat Flux

Mechanisms

3. EXCESSIVE FUEL TEMPERATURE

Excessive fuel temperature can be caused by overpower or

by reduced coolant flow. At thermal power and/or hydraulic

oscillations when the power peaks and/or the flow reductions

are very short and few, temporary over temperature (above

the designed limit) can occur without causing fuel failures

as normal cooling can quickly recover. To avoid excessive

fuel

temperature, which can cause damage to the fuel, knowledge

of the onset of the over heating phenomena is absolutely

necessary, both at the design stage and during the safe operation

of a reactor. There are complex correlations especially developed

for specific fuel bundle designs. These correlations contain

surface power, mass flow, system pressure and other parameters.

While analyzing the test results for a single fuel pin in

water and steam in an annular test section, it was recognized

that a single parameter, the void, is characterizing the

onset of the overheating phenomena regardless which critical

heat flux mechanism occurred.

4. MEASUREMENTS

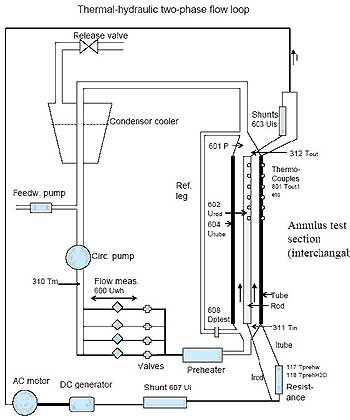

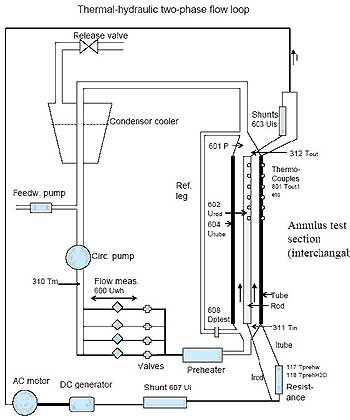

Measurements were been carried out in a two-phase flow test

loop consisting of two heated concentric tubes, the central

one representing a fuel rod while the outer pipe emanates

the heating power corresponding to the surrounding fuel rods

in a reactor core. This loop with an anular test section

height of 7 m is presently located at the Division of Nuclear

Engineering, KTH, Royal Institute of Technology, in Stockholm

and has been in operation for some thirty years first at

the Studsvik research establishment and then at KTH to simulate

thermal hydraulic conditions in Boiling Water Reactors. (Figure

2)

Total Power: 1 MW

Total mass flow rate: 1 kg/s

Max pressure: 25 Mpa.

Max lengt of the test section: 7m.

Figure 2. The loop and the test

section

5. TEST RESULTS

The results of these tests were studied to investigate

the occurrence of the onset of the excessive temperature

on the

surface of the inner and outer test tubes in this

annular flow system. The tests covered pressures of 30,

50 and 70 bar; sub-cooling 10ºC and 40ºC; mass

velocities between 250 and 2250 kg/m2s and a total

input power up to

580 kW, in this case with uniform power distribution. The

tests have been repeatedly performed in an annular test section

with a single fuel rod furnished with pin spacers, and 7

and 6 grid spacers alternatively. Then the test results were

evaluated. To calculate the steam quality, the continuity,

the heat and mass balance equations were applied. The Continuity Equations

Heat balance

Qtotal input = Qsubcooling to saturation + Qsteam building (1)

Q heat

Qsubcooling to

saturation heat used to increase

the temperature of the subcooled water to saturation temperature

Qsteam building heat used for vaporization of

part of the saturated water to steam

Mass balance

Winlet water = Wexit

water + Wexit steam (2)

W mass flow

The general definition of steam quality, sometimes called steam

value is:

x = Wsteam / ( Wwater + Wsteam) (3)

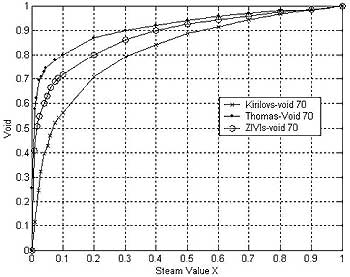

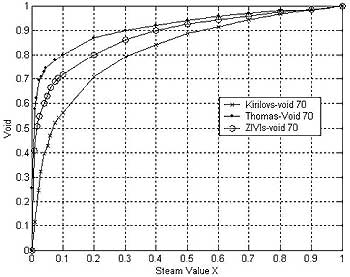

To calculate the void three known slip correlations;

Kirilov, Thoms and Zivi were used. The authors reached different

results indeed, however this does not influence the conclusions

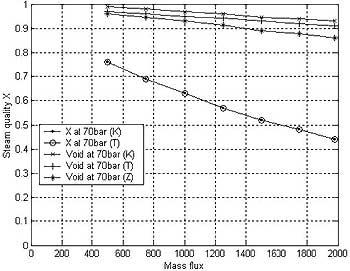

of this paper. (Figure 3).

Figure3. Comparison between different void correlations as

a function of steam quality

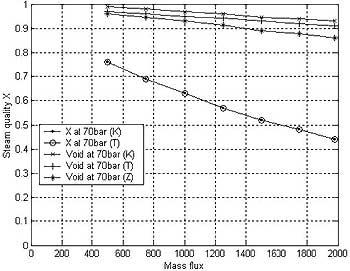

The most important result is, that

at the onset of the excessive surface temperature the void

value changes

merely between 0.88 to 0.99, while the steam quality changes

in a wide range from 0.45 to 0.75 (Figure 4)

Figure 4. Void and Steam Quality as a Function

of Mass-Flow at the Onset of the Abrupt Surface Temperature

Increase

There has been knowledge of this, however

- according to this author’s but this has

not been explicitly outlined. This helps to focus

on the void when planning

further test loop experiments, as well as when

monitoring the safety of operating reactors and

when designing new fuel

assemblies. By using the constraitns described

here -limiting the permissible void content - damage

of the fuel can be avoided.

6. AVOIDING EXCESSIVE FUEL TEMPERATURE

The awareness of this result helps the design of

a tool to avoid excessive fuel surface temperature and clad

failure

in

operating

reactors. To monitor the void during operation is presently

not feasible, however from the measured parameters, power,

power distribution, coolant flow, pressure etc. the steam

quality everywhere in the core can be calculated continuously

and the void can be deduced using steam quality versus void

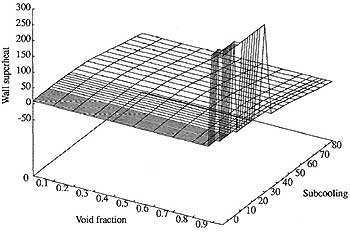

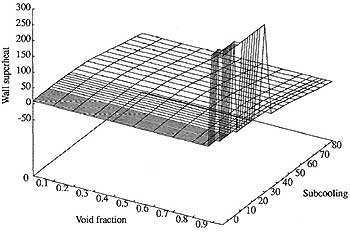

correlation derived from loop experiments. It is interesting

to note that an analytical model is described in the literature.

The mathematics is applied for a Freon loop and the deduced

figures coincide with the measurements from the experimental

loop mentioned above. The results are summarized in Figure

5. The abrupt increase of the temperature here too occurs

when the void value reaches around 90% for a wide range of

subcooling.

Figure 5. Prediction of critical heat flux for

Freon at p=1.5 bars, q ”= 190 kW/m2 at constant liquid

velocity of 0.5 m/

7. CONCLUSIONS

A series of experimental investigations on the maximum permissible

power production of Boiling Water Reactors (BWR) and the

effect of it on the fuel element’s surface temperature

was performed at the test facility located at KTH, Royal

Institute of Technology in Stockholm, Sweden. The

results show that the “void” is

the principal parameter for defining the onset of the excessive

surface temperature phenomena leading to burnout of a fuel

rod. |