European

Nuclear Society

e-news

issue 49: November 2015

Dear Reader,

As the new editor-in-chief, I would like to welcome you to the ENS News publication. Over the past ten years, Mr. Mark O’Donovan took great care to bring you a high-quality publication with relevant and interesting content. Now that he has decided to retire, it is up to me to strive and keep the quality of ENS News up to Mark’s standards.

The second half of 2015 was marked by numerous events spanning all fields of nuclear energy and nuclear research. Most importantly, all events in the nuclear industry are being focused on the up-coming UNFCCC COP21 climate change conference which will take place in December 2015 in Paris. The conference will bring together 196 nations who will have to hammer out a deal to reduce greenhouse gas emissions and agree to limit the effects of climate change. We all know the target of keeping the temperature increase to 2 degrees C by the end of the century.

The nuclear industry has a big stake in climate change mitigation politics, policies and scenarios. Environmentally, nuclear is a low-carbon source of energy and can help avoid CO2 emissions while providing a constant, large-scale power supply. It is indicative that the Intergovernmental Panel on Climate Change, the body which conducts peer-reviews on the science behind climate change, shows only eight out of more than a thousand scenarios which include a nuclear-free way of tackling climate change.

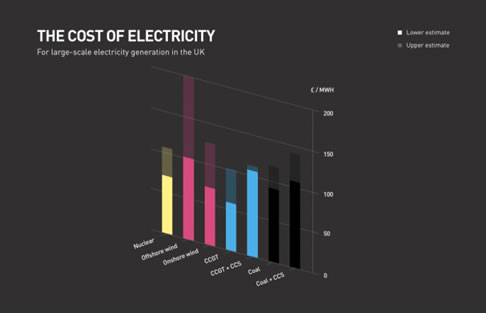

Economically, nuclear is very similar to renewable energy sources. Both have a high up-front cost but a very low marginal or operational cost. This means that both nuclear and renewable energy sources cost a lot of money to build but very little to maintain. At the moment, the increased use of renewables has pushed wholesale market prices down (because they cost very little to operate) but consumer prices have gone up (due to subsidies for the up-front costs). This situation is unsustainable for two reasons – utilities are not receiving enough money to cover their operational costs for other electricity generation technologies and consumers are paying every higher prices.

One country in Europe to have realised the issues brought in by subsidising renewables is the United Kingdom. After the landslide election victory of the Conservative party, Mr David Cameron has decided to cut subsidies to renewable energy installations. Then, in October, the UK government announced a deal with its Chinese counterparts that 33.5% of the Hinkley Point C nuclear power station will be paid for by Chinese investors. In addition, China will take a large stake in Sizewell B and perhaps even see a Chinese reactor being built at Bradwell. These plans for building four EPR reactors and one Chinese reactor, together with the three Westinghouse AP1000 reactors planned for Moorside and the Hitachi GE ABWR planned for Wylfa, will bring online nine new reactors with a total power output of around 11 GW.

The UK’s push for a nuclear new build programme comes in the context of the EU’s pilot project for building an Energy Union. EU Commissioner Maroš Šefčovič’s plans for interconnecting and decarbonising Europe through sustainable and competitive energy technologies will require a lot of work and a completely new energy market design. To this end, the EC opened a public consultation on the topic. The main challenges to be addressed are related to ensuring affordable consumer prices for electricity while not condemning utilities to a life of selling their production at below-cost levels.

The economics of electricity markets will play an important role in the COP21 negotiations when ministers try to hammer out a deal to save the planet from overheating. Let us hope that the benefits of using nuclear energy, which is more like renewables than many are ready to acknowledge, will be taken into account once decision-time comes around.

Lubomir Mitev

Editor-in-Chief, ENS NEWS

http://www.euronuclear.org/e-news/e-news-49/presidents-contribution.htm

|

On June 22nd, I attended the joint ENS-SFEN Young Generation Forum in Paris. All our readers know the importance of the young generation in our 23 member societies: they are the future of nuclear energy in Europe and beyond. The forum was held in “la Cité des Sciences et de l’Industrie” at La Villette, in the northern part of Paris. It was a special privilege for me to open the event as ENS President, all the more since I grew up in the vicinity of La Villette in the mid fifties, when la “Cité des Sciences” was still thirty years ahead. But let me quote my own words: |

“Distinguished delegates, Ladies and Gentlemen,

It is customary to begin such a speech by thanking the organizers, Sophie Missirian at SFEN and Eileen RADDE at ENS, both chair ladies of the young generation networks for inviting the first speaker. This, I will not fail to do. But my reasons will be somewhat non conventional.

The first reason is both related to youth (you in the audience), and to my own life. Indeed, I grew up less than a mile away from this very spot in La Cité des Sciences at la Villette. It was in the mid fifties and the early sixties. This was still an immigration suburb where butchery was practiced at a large scale, maybe you will have time to take a look at the transformed XIXth century buildings during the 3 days of the conference: Avenue du Charolais and la Grande Halle, only a 15 minute walk from this building. In those days, the Paris circular highway did not exist, it was under early construction stage. France was evolving rapidly from its post war colonial empire. Of course the internet was 40 to 50 years away, even conventional copper wire telephones were quite scarce for the ordinary Frenchman or woman.

Nuclear did exist however first for military applications since our great political leader of the time wanted independence from the Americans. They had nearly pushed him into political oblivion during the Second World War and he could not trust them completely in all nuclear matters as the English leaders would do, on the other side of the channel.

On the civilian side, generation one small power reactors were commissioned with natural uranium as fuel and graphite as moderator. Later, in the late seventies we switched to what was at the time a leading American technology: the Pressurised Water Reactors (PWR’s) of the Westinghouse design. It is now forgotten that it took us some time in France, De Gaulle had already left power when it happened and we were quite successful. In a very short period of time we built 54 Westinghouse licensed reactors and 4 on our own with Framatome. Most of you know them under the name of Generation 2 reactors and we plan to extend their lifetime up to 60 years, which would bring the most recent units the N4 at Civaux and Chooz well beyond 2050. Of course we were not alone in Europe to deploy nuclear power for electricity generation. Western and northern countries did the same not only with gas graphite reactors (the British), with PWR’s but also with Boiling Water Reactors, the BWR’s. Central and Eastern Europe (and also Finland at Loviisa) adopted Russian designs, the VVER’s which in Russian means something similar to Pressurized Water Reactors. There were also a limited number of graphite reactors, the RBMK’s now shut down, Ignalinia in Lithuania and Candu technology with heavy water in Romania, to the East on the Cernavoda site.

But this is the past, and one cannot live only by looking in the mirror at past history all the more when speaking to an audience of young people, the young generation of 23 nuclear societies all around Europe. The present is both a divided Europe, evenly split into 2 halves about nuclear energy and a massive energy transformation underway because of climate change. It is quite relevant that you and the organizers have chosen the theme of climate change and nuclear as a key part of the solution in the fight against those problems for your bi annual gathering. Let me comment that the energy transformation has its own name in the different European countries and that it is led and pursued according to the political cultures of the 28 Member States. To speak first of the major countries, Die Energie Wende in Germany was decided by the political leadership, Kanzlerin Merkel in a few weeks in 2011. In my own country France, the new law Transition Energétique pour la Croissance Verte, the first part of which can be translated as Energy Transition took months and months of debate, I would say a good 2 years. It is not yet in force, even though the legislative process is nearing completion1. In Europe the Commission has both to lead the climate change energy transformation and to respect the founding treaties which recognize energy choices as a fundamental right and prerogative of each of the 28 Member States. This is why it has come up with the concept of energy union and its main objectives all climate change compatible, with low carbon technologies and energy sources, with a sophisticated governance mechanism and with European wide debates about market design. Let me point out that nuclear is present in the wider European energy debate, through its European Nuclear Energy Forum a high level meeting of ministers, company CEO’s, high level representatives of the civil society, Directors General of main European associations. Its last plenary was held in Praha, Czech Republic at the end of May. The Czech Energy Minister Mr. Mladek concluded among other things that Nuclear Energy has its place in the European Union Energy Portfolio and that a market design favorable for nuclear investment has not yet been achieved. It needs further work which I hope is underway in Europe and at the Commission.

There is another upcoming political event at the end of this year in Paris : the twenty first Conference of Parties which you know under its acronym: COP 21. It is established under a United Nations Framework to fight Climate Change and it is the precise meaning of another acronym, UNFCC. It is important because of the urgency to act and because past COP gatherings have not achieved sufficient commitments from the Green House Gas emitting countries to reduce emissions and reach what experts consider as a tolerable level, synthetized in the 2°C scenario. One of today’s speakers, Madame Masson Delmotte will give you more information about that. It is hoped but it is only a hope at the present stage of negotiations that more substantial commitments will be reached this year getting our future planet on a safer course. Reaching some kind of agreement between 196 countries, the parties to the United Nations Framework is not an easy task. It is mostly a task for the Parties themselves, their political leaders and the technical negotiators they have designated. However, all of us in this room Young or not so Young have a part to play, even if we are several levels below the negotiators.

For nearly 30 years your elders (and that includes me) have been convinced that nuclear is a low carbon technology, that it does note emit CO2 when generating nuclear heat even though carbon dioxide is emitted when the materials to build a nuclear plant are fabricated (steel, concrete, other alloys, fuel oxides and so forth). Therefore, yes we believe that nuclear is a key part of the solution to climate change problems. Have we been good at convincing others ? Well honestly, we the elders think not so much :

The community of climate change experts and negociators which is a wide and respected community coined a sentence, a saying at a previous conference

“DO NOT NUKE THE CLIMATE”

And it was not only a saying, it had financial implications, important ones.

This is why we, the elders and their nuclear industry need you the young generation of the European nuclear societies to better formulate the message with all the tools your generation can muster : the web, the social networks, instant image, photographs and video projections using the afore media….. And of course and above all, we need your personal conviction.

Technicalities of why nuclear is part of the solution, a key part, I would say, I will leave to my distinguished friend and colleague, CEA Nuclear Energy Director Christophe BEHAR. He is due to speak this afternoon, just after lunch.

I can see in your program that you will be covering many important subjects concerning nuclear energy in the next 3 days : nuclear waste, geological disposal in the northern countries and societal impact tomorrow, changing electricity markets and the role of nuclear energy in the change on Wednesday and Generation IV Reactors and closed fuel cycle, that should also be on Wednesday.

They are all important to shape the future of nuclear energy, the future that belongs to you, the Young Generation of the European Nuclear Societies.”

1The speech was delivered on June 22. The energy transition law was voted by the French Parliament a month later, at the end of July 2015.

http://www.euronuclear.org/e-news/e-news-49/ygn-report.htm

The reactor fuel performance conference TopFuel 2015 takes place every third year in Europe and is organized by the European Nuclear Society (ENS). When the conference is not in Europe, the American Nuclear Society and the Atomic Energy Society of Japan, together with the Chinese Nuclear Society and the Korean Nuclear Society, host the event in their respective continent.

After the European conferences in Paris, France, in 2009 and in Manchester, UK, in 2012, the nuclear fuel community met in Zürich, Switzerland in September 2015. As usual the TopFuel conference represented a great opportunity to meet the whole nuclear fuel community. The participants include operators, vendors, nuclear regulatory authorities, technical support organisations (TSO), research institutes and universities worldwide. At the same time, several PhD students and postdoc researchers used the change to present their own results and to come and keep in touch with the nuclear fuel community.

The TopFuel 2015 conference was opened by the chair, Dr. Marco Streit (Paul Scherrer Institute, President of Swiss Nuclear Society) and the programme committee chair Johannes Bertsch (Paul Scherrer Institute). The openning session included a panel discussion under the title Upcoming Challenges Of The Fuel Market and was moderated by Tony Williams (Axpo Power AG, Switzerland). The fuel vendors GNF, Westinghouse, AREVA, ENUSA and Rosatom announced a 40% overcapacity in fuel assembly production in Europe. Several reasons exist for this, e.g. the immediate shutdown of several nuclear power plants in Germany after the 2011 accident at the Fukushima nuclear power plant. In general, several vendors expect a consolidation and / or collaborations in the European fuel market in the future. The openning session was completed by an overview of the activities of the OECD/NEA Expert Group on Accident Tolerant Fuels for Light Water Reactors, focussing on fundamental properties and behavior under normal operation and accident conditions.

After the opening session the participants had the choice between several parallel technical sessions. The sessions highlighted new trends, experiences, developments and R&D results in the fields of operation, operational transients, design basis accidents (incl. LOCA) and their modelling / simulation with computer codes. For example, new experimental results were presented by JRC-ITU (European Commission) regarding micro-hardness and local properties of high burnup UO2 fuel. In spite of the increase of the fuel burn-up in many commercial reactors worldwide there is still R&D needed to understand and characterize in detail the processes ongoing in the high burnup structure occurring in the fuel pellet periphery.

Beside these topics the development of accident tolerant fuels was given attention in three sessions of the conference. As is well known, this topic has increased in interest in the last years. It seems that these developments are challenging for all involved parties. Nevertheless, Westinghouse pointed out that the first test with accident tolerant fuel in a commercial reactor was planned for 2022.

In addition, the wide spectrum of topics in the conference program was completed by two sessions about investigation of fuel for fast Gen-IV reactors (ASGARD) and three sessions about spent fuel.

After three days of interesting and great presentations, lectures, discussions and get-together of the fuel community the conference participants could take the opportunity to attend a technical tour. They could choose between a visit of the hot labs of the Paul Scherrer Institute (PSI), of the nuclear power plant Gösgen, or to go to Mont Terri Rock Laboratory for nuclear waste repository research all located in Switzerland.

TopFuel 2016 will take place in Idaho, USA, in 2016.

http://www.euronuclear.org/e-news/e-news-49/corrosion-and hydrogen.htm

Presented during the TopFuel 2015 conference

DAVID SCHRIRE

Vattenfall Nuclear Fuel

SE 162 87 Stockholm, Sweden

Tel: +46-76 809 6596, Email: david.schrire@vattenfall.com

KRISTINA KARLSSON

Forsmarks Kraftgrupp AB

SE 742 03 Östhammar, Sweden

Tel: +46-173 81293, Email: kka@forsmark.vattenfall.se

GÖRAN BLOMBERG

Studsvik Nuclear AB

SE 611 82 Nyköping, Sweden

Tel: +46- 155 221653, Email: goran.blomberg@studsvik.se

ANDREAS MOECKEL

AREVA GmbH

Paul-Gossen-Straße 100, 91052 Erlangen, Germany

Tel: +49-9131-900 95316, Email: andreas.moeckel@areva.com

The hydrogen pickup behaviour in BWR fuel channels is an important characteristic not least because the hydrogen is implicated in the irradiation growth behaviour which can lead to distortion. It has been observed that fuel channels with extensive control blade exposure (i.e. adjacent to a partially or fully inserted control blade for a significant amount of time) early in life tend to bow towards the control blade side late in life. Since bow is understood to result from a difference in growth between opposite sides of a channel, it can be assumed that the sides adjacent to a control blade early in life tend to grow more later in life. Another consequence of operation adjacent to a control blade is that the outer surface of the channel facing the control blade (or control blade handle) develops what is commonly known as “shadow corrosion”. Shadow corrosion occurs on Zr-base alloys in contact with or in close proximity to other metallic alloys in the reactor core radiation field in BWRs or other reactors with simi-larly oxidising water conditions.

Due to an issue with thermal fatigue of the control blade shafts, the Forsmark 3 plant operated for 7 months with all the control blades inserted 500 mm into the core. The bottom sections of fuel channels at all burnup levels were thus continuously adjacent to control blades during this time. Taking ad-vantage of this unique opportunity, at the end of this cycle it was decided to cut out samples from a 1-cycle and a 6-cycle Zircaloy-2 channel that both experienced this unusual control blade exposure without any significant prior control blade exposure, for post-irradiation hydrogen measurements and metallographic examination at the Studsvik hot cell laboratory.

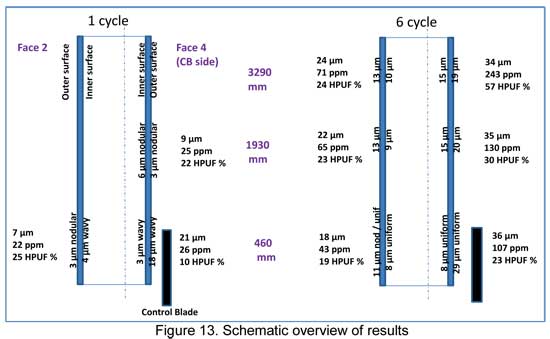

The results of the post-irradiation examinations showed that:

The shadow corrosion rate was somewhat higher on the 6-cycle channel than on the 1-cycle channel.

For the 1-cycle channel the side adjacent to the control blade and the opposite side at the same elevation had the same low hydrogen concentration, showing that the early-in-life con-trol blade exposure did not cause any significant increase in hydrogen pickup.

For the 6-cycle channel the samples on the side adjacent to the control blade had far higher hydrogen concentrations than the opposite side at the same elevations. This difference was higher at the higher elevation samples than at the elevation directly adjacent to the control blade.

Since the 1-cycle sample from the side adjacent to the control blade had significant shadow corrosion on the outer surface but about the same low hydrogen content as the sample at the same elevation from the opposite side (without any shadow corrosion), it is concluded that the shadow corrosion from the proximity to the control blade per se did not make any significant contribution to the hydrogen pickup. For the 6-cycle channel there was a larger increase in the hydrogen concentration between the control blade side and the opposite side at higher elevations, well above the zone in direct proximi-ty to the control blade. Since this could not be due to shadow corrosion, it is concluded that the higher hydrogen pickup on the control blade side of the 6-cycle channel is probably due to some other effect of the different conditions on the two sides of the assembly, for instance the local power, fast neutron flux and void distribution.

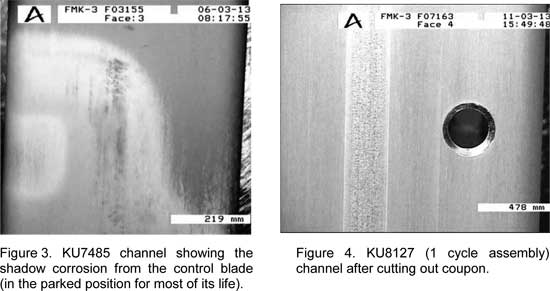

The hydrogen pickup behaviour in BWR fuel channels is an important characteristic not least because the hydrogen is implicated in the irradiation growth behaviour which can lead to distortion. It has been observed that fuel channels with extensive control blade exposure (i.e. adjacent to a partially or fully inserted control blade for a significant amount of time) early in life tend to bow towards the control blade side late in life [1]. Since bow is understood to result from a difference in growth between opposite sides of a channel, it can be assumed that the sides adjacent to a control blade early in life tend to grow more later in life. Another consequence of operation adjacent to a control blade is that the outer surface of the channel facing the control blade (or control blade handle) develops what is commonly known as “shadow corrosion”. Shadow corrosion occurs on Zr-base alloys in contact with or in close proximity to other metallic alloys in the reactor core radiation field in BWRs or other reactors with similarly oxidising water conditions.

Vattenfall’s Swedish BWRs are normally operated such that medium burnup fuel assemblies (typically in their 3rd year of operation) are placed in control cells with extensive control blade exposure, while fresh and high burnup fuel have a minimum of control blade exposure during normal operation. However, due to an issue with thermal fatigue of the control blade extender shafts, the Forsmark 3 plant operated for seven months (cycle 24B) with all the control blades inserted 500 mm (14 %) into the core [2]. The lowest 500 mm of fuel channels at all burnup levels were thus continuously adjacent to control blades during this time.

Taking advantage of this unique opportunity, at the end of this cycle it was decided to examine samples from a 1-cycle and a 6-cycle Zircaloy-2 channel that both experienced this unusual control blade exposure without any significant prior control blade exposure.

Both the fuel channels were from ATRIUMTM 10B fuel, with nominally identical channel design and material. The channels were fully recrystallized Zircaloy-2, with a constant wall thickness of 2.3 mm. In the Forsmark 3 lattice the channel-channel water gap is nominally 19.4 mm on the control blade sides and 12.9 mm on the opposite sides. Forsmark 3 operates with normal water chemistry (NWC), i.e. with no injection of hydrogen, zinc or noble metals.

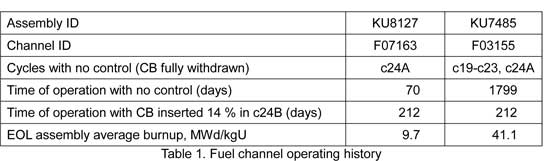

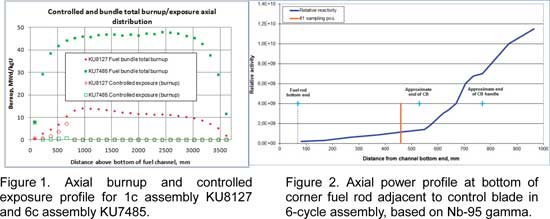

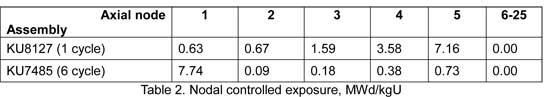

The assembly and channel overall operating history is summarised in Table 1. The node-wise axial burnup distributions of the 1-cycle fuel bundle KU8127 and 6-cycle fuel bundle KU7485 are shown in Figure 1 together with the equivalent controlled exposures for each node. The nodal controlled exposure is the cumulative burnup for the node for that time in which the control blade (or its handle) has been inserted into that node. This metric is equally weighted irrespective of when in life the control blade has been present in the node. As can be seen in Figure 1, for both assemblies/channels there was zero control blade exposure above the lowest 5 nodes at any time in the fuel lifetime. In the lowermost node (node 1) the controlled exposure is equal to the total burnup in that node – this is because with the control blade fully withdrawn (parked position) the control blade handle extends into the first node, so irrespective of the control blade position this node experiences “control”. The shadow corrosion formed from proximity to the control blade handle in the withdrawn position is clearly seen in the lower part of the 6c channel (Figure 3). For the 1c assembly KU8127 the controlled exposure in nodes 2-5 is almost as much as the total burnup, since those nodes only experienced about 70 days of uncontrolled operation prior to the partial blade insertion. For the 6c assembly KU7485 the controlled exposure in nodes 2-5 is much lower than for the 1c assembly since this assembly operated at a much lower power during cycle 24B (it had a higher burnup and was on the core periphery), and represents only a very small fraction of the total burnup for these nodes, see Table 2. It should be noted that the 6c assembly KU7485 was located on the core periphery for its last 3 cycles, so the control blade corner faced inwards. The assembly achieved a burnup of 35.2 MWd/kgU during its first 3 cycles, but only an additional 5.9 MWd/kgU in its last 3 cycles on the periphery. Nonetheless, the fuel rods at both sides of the assembly (adjacent to the channel sampling positions) had similar end of life burnups and so the channel fast neutron fluences were probably relatively similar on both sides during the first 3 cycles and only differed much in the last 3 cycles.

Figure 2 shows the axial power profile in the lower part of the corner fuel rod adjacent to the control blade corner (a1 rod) during the last cycle of operation, based on Nb-95 gamma spectrometry. The effect of the partially inserted control blade, as well as the control blade handle, are clearly seen.

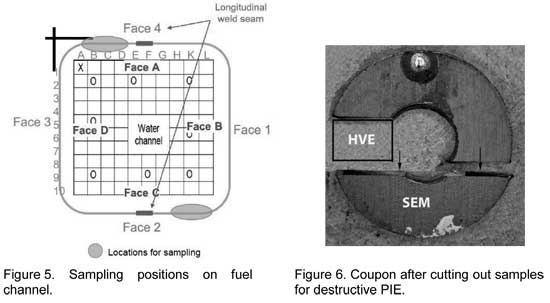

Circular samples (coupons) were cut from the CB (Control Blade) side (Face 4) and the non- CB side (Face 2) beside the longitudinal weld seam, see Figures 4 and 5 below. On each side, coupons were cut at three axial positions: 460 mm, 1930 mm and 3290 mm above the bottom of the channel. A new replacement channel was obtained for the continued operation of the 1-cycle bundle, since its original channel had to be scrapped after the coupons had been cut out.

The coupons were positioned by drilling a pilot hole through the channel wall, marking the upper end with the pilot drill, and then cutting out the coupons with a core drill, see Figure 6 below.

Channel bow measurements were performed on both channels before the sample cutting. The maximum bow was as follows, where a negative value is away from the CB.

KU8127 (1 cycle) x-direction -0.35 mm y-direction -0.46 mm

KU7485 (6 cycle) x-direction +0.98 mm y-direction +2.26 mm

The channel coupons were retrieved from the shipping container, and photographed to rec-ord the inner and outer surface appearance. Hot vacuum extraction (HVE) and scanning electron microscopy (SEM) samples were cut out as shown in Figure 6.

The hydrogen content was measured by HVE using an ELTRA OH-900 Hydrogen Determina-tor as follows: The samples (weighing about 0.1 g) were placed in a graphite crucible and heated up to about 2000 °C with argon as carrier gas. Any CO that might be present was removed by passing the gas mixture through Schütze’s reagent (I2O5) to oxidize the CO to CO2 which was subsequently removed by chemical reaction with NaOH. The gas mixture of argon and hydrogen then passed through a thermal conductivity detector with low drift, high resolution and wide measuring range. The hydrogen concentration was determined by an integrator. Before the measurements, the HVE equipment was calibrated using certified Ti-based standards with 62.5 ± 3.2 ppm hydrogen content. Although the absolute accuracy of the hydrogen determination using HVE is no better than the relative accuracy of the calibra-tion standards (in this case about 5 %), the reproducibility/precision has previously been found to be better than this, except at very low concentrations. The measurements were per-formed on samples which included any attached oxide, so the reported hydrogen concentrations refer to the total evolved hydrogen relative to the total sample weight.

Cross-sectional arcs were cut out for scanning electron microscopy (SEM), where the inner and outer surface could be examined along a plane just above the word “SEM” in Figure 6. The samples were embedded in epoxy resin, ground and polished with 0.04 μm colloidal SiO2 suspension as a final oxide polishing step. The examinations were performed in a JEOL 6300 SEM. Micrographs were taken in BEI-mode (Backscatter Electron Imaging) using dif-ferent instrument settings for optimised imaging of the oxide or the hydrides. The oxide thickness was evaluated from the micrographs acquired in the SEM. The average thickness was determined by measuring the total oxide area in each micrograph using a Leica QWin image analysis software. The oxide area was divided by the width of the measured oxide layer in each micrograph to obtain the average oxide thickness. This method takes into ac-count variations in oxide thickness and delamination or separation of oxide layers.

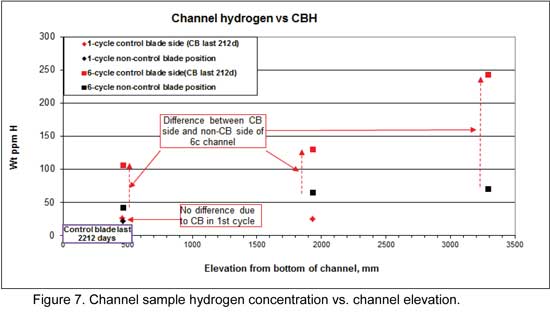

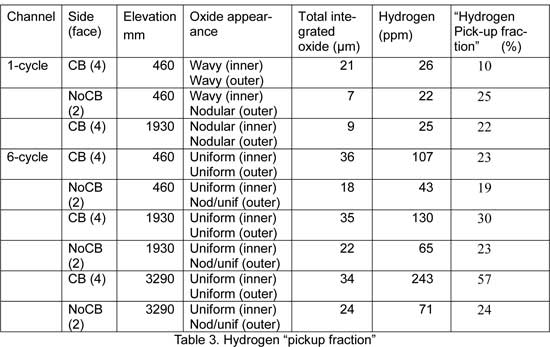

The hydrogen concentrations measured by HVE are shown in Figure 7. The red symbols represent the measurements on the control blade side (face 4 in Figure 5) and the black symbols represent the measurements on the non-control blade side (face 2 in Figure 5). The 1-cycle channel (diamond-shaped symbols in Figure 7) had a low concentration of just over 20 ppm for both the CB side (face 4 in Figure 5) and the non-CB side (face 2 in Figure 5) at the lowest elevation (460 mm above the bottom of the channel). At this elevation the control blade was adjacent to the CB side during cycle 24B. At the mid-height elevation (1930 mm) the hydrogen was only measured on the CB side and was essentially the same as at the lower elevation.

The 6-cycle channel (square symbols in Figure 7) had very much higher hydrogen levels in all the samples measured. On the non-CB side, the hydrogen concentration increased with elevation from just over 40 ppm at the lowest position to just over 70 ppm at the top sample. On the CB side, the hydrogen concentration was very much higher, increasing with elevation from just over 100 ppm at the lowest position to just over 240 ppm at the top sample.

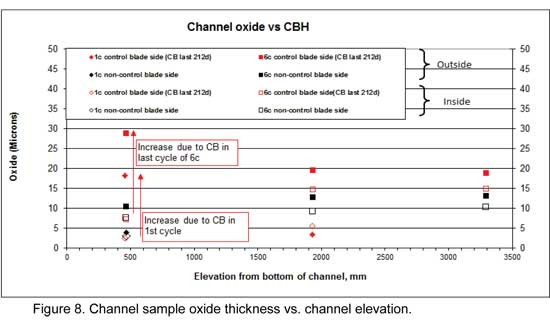

The average oxide thicknesses measured in the SEM are shown in Figure 8. The red sym-bols represent the measurements on the control blade side (face 4 in Figure 5) and the black symbols represent the measurements on the non-control blade side (face 2 in Figure 5). The filled symbols are the oxide thickness on the outside of the channel wall and the open sym-bols are the oxide thickness on the inner surface. The oxide layer appearance (topography) varied between the samples and frequently between the inner and outer surface of the same coupon. The oxide appearance is described qualitatively below.

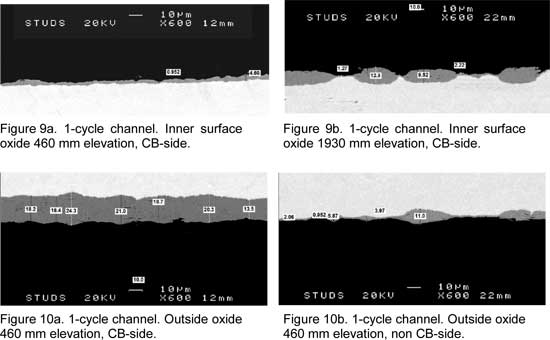

1-cycle channel. The inner oxide layer was rather uniform in both the 1-cycle samples at the lowest elevation but thicker nodules were present at the 1930 mm elevation (Figures 9a and 9b). The outer surface oxide layer was much thicker, and relatively uniform, in the sample that had been adjacent to the control blade (460 mm elevation on CB-side), compared to the other samples (Figures 10a and 10b).

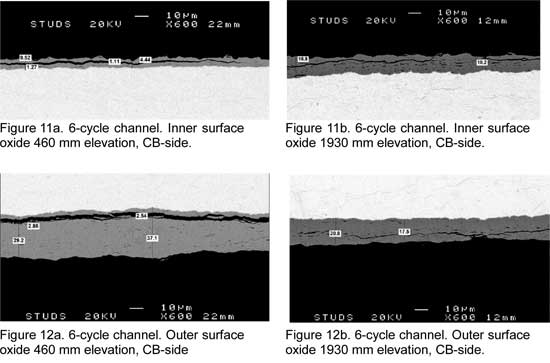

6-cycle channel. The inner oxide layer was rather even in the 6-cycle samples (Figures 11a and 11b). The average thickness was the same on both sides at the 460 mm elevation, and thicker higher up. The outer surface oxide layer was thicker in the sample that had been ad-jacent to the control blade (460 mm elevation on CB-side), compared to the other samples. (Figures 12a and 12b). Both the inner surface and outer surface oxide showed some appar-ent tendency to delamination (cracks) which was not seen in the 1-cycle samples.

The oxide appearance has been broken down into the following rough categories, and the different sample surfaces are characterized accordingly in Table 3:

“Wavy” where there is a continuous oxide coverage, but the thickness varies signifi-cantly with a wavy appearance, see e.g. Figure 9a.

“Nodular” ” where the individual nodules are about an order of magnitude thicker than the thin oxide separating them, see e.g. Figures 9b and 10b.

“Uniform” where the thickness varies less than about a factor 2, irrespective of the ac-tual thickness or condition of the layer, see e.g. Figures 11b and 12b.

It is considered likely that the wavy or nodular oxide appearance seen in the 1-cycle channel would eventually progress to the continuous oxide film categorised as “uniform”.

Shadow corrosion. The shadow oxide thickness (oxide attributable to the shadow corrosion) can be estimated from the difference in oxide thickness between the CB-side outer surface at the 460 mm elevation, compared to the non-CB side at the same elevation. The shadow cor-rosion can also be estimated from the difference in oxide thickness between the outer surface (facing the control blade) and the inner surface, at the 460 mm elevation. In both cases for the 1-cycle channel, this results in an apparent shadow corrosion during cycle 24B of about 15 µm, as indicated in Figure 8. For the 6-cycle channel, the shadow oxide thick-ness estimated in the same way results in an apparent shadow corrosion during cycle 24B of 18-22 µm, as indicated in Figure 8. It thus seems that the 212 days of exposure to the partial-ly inserted control blade resulted in a somewhat thicker shadow corrosion on the 6-cycle channel than on the 1-cycle channel, despite the fact that the latter had only operated for 70 days prior to the control blade exposure and thus not built up a thick oxide layer prior to the control blade exposure.

This observation is notable when bearing in mind the fact that the 6-cycle channel operated in a far lower radiation field during cycle 24B when the shadow corrosion occurred. Although not a perfect measure of the radiation field, the difference in “controlled exposure” (fuel bun-dle nodal burnup accumulation while adjacent to the control blade) gives some indication of this difference between the two channels. In the controlled node 3 (corresponding to the 460 mm elevation coupons) this parameter was almost an order of magnitude lower for the 6-cycle assembly than for the 1-cycle assembly. Since shadow corrosion is believed to be a form of radiation assisted galvanic corrosion [3], if the radiation field intensity plays a role it might have been expected that the shadow corrosion should have been equal or greater in the 1-cycle channel. However, the exact distance between the control blade surface and the channel might vary slightly from case to case, which could potentially explain the faster shadow corrosion in the 6-cycle channel.

General corrosion. The corrosion on all the sample surfaces from the 1-cycle channel, apart from the surface exposed to the control blade with shadow corrosion, had average oxide thicknesses ranging from just under 3 µm to just over 5 µm at both the 460 mm and the 1930 mm elevation (Figure 8). For the 6-cycle channel, however, there was a more noticea-ble (factor 2) increase in the general oxide thickness from the 460 mm to the 1930 mm elevation (Figure 8). At the 1930 mm elevation both the inner and outer surfaces of the 1-cycle channel had characteristically nodular oxide appearance, see Figure 9b and Table 3. The oxide on the 6-cycle channel at the same elevation had a more uniform appearance, see Figure 11b and 12b. Assuming that the 6-cycle channel had a similar oxide layer at the end of its first cycle to the 1-cycle channel then the subsequent growth of the oxide in the later cycles primarily consisted of “filling in” the oxide layer between the nodules, rather than a further increase in the depth of the nodules.

Hydrogen pickup. The measured hydrogen content in three coupons from the 1-cycle channel all showed low and similar levels of 22-26 ppm, despite the 3-times thicker total ox-ide thickness (inner and outer surface) for the 460 mm sample exposed to the control blade, see Figure 7. There was thus no indication of any additional hydrogen pickup due to shadow corrosion in these channel samples. The 6-cycle channel sample exposed to the control blade, however, had a far higher hydrogen content than the sample from the opposite side at the same elevation, see Figure 7. The difference between the control blade side (face 4) and the opposite side (face 2) was even more striking for the two higher elevations. Since the higher elevations were never exposed to control blade presence, the higher hydrogen level in face 4 cannot be explained by shadow corrosion due to control blade proximity, which has been claimed in other cases [1, 4, 5]. The apparent “hydrogen pickup fraction” for the sample positions where both hydrogen concentration and inner and outer surface average oxide thickness were measured, is shown in Table 3, assuming the oxide has 100% theoretical density.

As explained above, it would seem that the shadow corrosion (estimated to be about 15 µm for the 1-cycle channel) did not result in significant hydrogen pickup. Similarly, for the 6-cycle channel, the total hydrogen content in the CB side at 460 mm elevation (which experienced control blade proximity and shadow corrosion) is lower than for the higher elevations on the same side. So what could have caused the higher total hydrogen pickup (and apparent pickup fraction) on the CB side of the 6-cycle assembly compared to the opposite side?

One difference between the two channel sides is that the channel-channel water gap is larg-er on the CB-side (see section 2 above). However, it is not evident that this would affect the hydrogen pickup, since the non-boiling bypass water was about the same temperature on both sides when the assembly operated in more central positions in the core in the first three cycles. Instead, it is more likely that the last 3 cycles when the assembly was in the same core position on the periphery may have had some effect.

The entire assembly had a very low average void in the last three cycles (exit void of about 25 %), with no bulk boiling calculated for the lowest 13 nodes including the 1930 mm eleva-tion, so presumably what void there was occurred mainly on the side facing the core centre (towards the CB sides). The inlet temperature was 275-277 ºC, and since there was no bulk boiling in the bypass the exit temperature on both sides was below 286 ºC. Since the bypass flow area is larger, and the heat flux lower, on the outer facing surface the bypass water tem-perature (and thus channel temperature) was somewhat lower compared to the inboard-facing sides. However, it does not seem likely that the slightly higher bypass water tempera-ture on the CB-side than the opposite side could explain the difference in hydrogen pickup, since the hydrogen content at both the 460 mm and 1930 mm levels on the CB-side were higher than the hydrogen content in the opposite side at higher elevations (where the chan-nel temperature would also have been higher).

The non-CB side had a lower fast neutron fluence than the CB-side during the last three cy-cles, which may provide an explanation for the difference in behaviour. It is possible that although both sides of the channel had experienced substantial irradiation damage during the first three cycles of operation, the outer-facing sides experienced insufficient fast neutron flux in the last three cycles to undergo the rapid increase in hydrogen uptake that is typical for irradiated Zircaloy-2 in in-pile BWR conditions after high exposure.

Neither channel had appreciable bow. The 1 cycle channel had a very small negative bow (i.e. away from the CB corner), remaining from the as-fabricated condition (Forsmark 3 channels are oriented such that any existing bow is away from the control blade). The 6 cycle channel has a small bow towards the CB sides, which is not surprising considering the higher neutron fluence and hydrogen content on those sides.

The results of the post-irradiation examinations showed that:

The shadow corrosion rate was somewhat higher on the 6-cycle channel than on the 1-cycle channel.

For the 1-cycle channel the side adjacent to the control blade and the opposite side at the same elevation had essentially the same low hydrogen concentration, showing that the early-in-life control blade exposure did not cause any significant increase in hydrogen pickup.

For the 6-cycle channel the samples on the side adjacent to the control blade had far higher hydrogen concentrations than the opposite side at the same elevations. This difference was higher at the higher elevation samples than at the elevation directly adjacent to the control blade.

Since the 1-cycle sample from the side adjacent to the control blade had significant shadow corrosion on the outer surface but about the same low hydrogen content as the sample at the same elevation from the opposite side (without any shadow corro-sion), it is concluded that the shadow corrosion from the proximity to the control blade per se does not make any significant contribution to the hydrogen pickup.

For the 6-cycle channel there was a larger increase in the hydrogen concentration be-tween the control blade side and the opposite side at higher elevations, well above the zone in direct proximity to the control blade. Since the difference at the higher el-evations could not be due to shadow corrosion, it is concluded that the higher hydrogen pickup on the control blade side of the 6-cycle channel is probably related to thicker oxide and is due to some other effect of the different conditions on the two sides of the assembly, for instance the local power, fast neutron flux and void distribu-tion.

The authors are grateful to Jesper Kierkegaard for assistance in selecting the candidate channels and insights into relevant aspects of their operation.

“Shadow Corrosion Resulting in Fuel Channel Bowing”. USNRC Information Notice 89-69 Supplement 1, 25 August 2003.

Operating Experience from Swedish Nuclear Power Plants 2008. Kärnkraftsäkerhet och Utbildning AB, 2009.

G Lysell, A-C Nystrand and M Ullberg, “Shadow Corrosion Mechanism of Zircaloy”, ASTM STP 1467, 2005.

S. T. Mahmood et al., “Channel Bow in Boiling Water Reactors – Hot Cell Examination Results and Correlation to Measured Bow”, Proc. Int. LWR Fuel Performance Meeting San Francisco, California, Sept. 30 – Oct. 3, 2007.

http://www.euronuclear.org/e-news/e-news-49/effect-of-stress.htm

Presented during the TopFuel 2015 conference

M.N. CINBIZ

Department of Mechanical and Nuclear Engineering, Pennsylvania State University

University Park, PA 16802, USA

D.A. KOSS

Department of Materials Science and Engineering, Pennsylvania State University

University Park, PA 16802, USA

A.T. MOTTA

Department of Mechanical and Nuclear Engineering, and

Department of Materials Science and Engineering, Pennsylvania State University,

University Park PA, 16802, USA

During vacuum drying operations, spent fuel cladding typically can experience high internal gas pressure loading that can cause the precipitation of dissolved hydrides into a radial configuration which can degrade the mechanical properties of the cladding during dry-cask storage/transportation conditions. Because the stress state experienced by the cladding is multiaxial, this study investigates the role of stress state on hydride reorientation. Zircaloy-4 sheet test specimen configurations were designed to induce a range of multiaxial stress states in material, which was previously charged with hydrogen contents ≈180 wt. ppm. The specimens were subjected to thermo-mechanical treatments designed to form radial hydrides, and the critical stress to reorient hydrides was determined in each case by matching the stress state calculated by finite element analysis at a specific location within the specimen to the hydride microstructures at that location. The results show that the critical value of the major principal stress to initiate radial hydride precipitation decreases from 155MPa to 115MPa as the stress state changes from uniaxial tension to plane-strain tension. Thus, increasing the degree of stress biaxiality enhances radial hydride precipitation, and the effect of stress state should be considered when the assessing the probability of hydride reorientation during drying-operation.

As a result of waterside corrosion reactions hydrogen is picked up by the nuclear fuel cladding during operation in light water reactors. While up to 120 wt. ppm of hydrogen can typically be in solution during operation, when the fuel is removed from the reactor nearly all of the hydrogen precipitates as hydride particles. The precipitated hydride particles can degrade the mechanical properties of the cladding material[1]. In particular, the potential for hydride embrittlement of the cladding tubes increases drastically if the hydride platelets are reoriented from their normal circumferential orientation onto the radial direction of the cladding as “radial” hydrides [2, 3]. Hydride reorientation can occur as a result of heat treatments during the vacuum drying process in which the cladding temperature can reach up to 400°C, causing the hydrides to partially or completely dissolve. During subsequent cool-down, the hydrogen in solid solution can re-precipitate as radial hydride platelets if the hoop stress caused by the internal pressure of the gaseous fission products and fill gases exceeds the threshold stress level for formation of radial hydrides [4]. Hydride reorientation has been studied for either internally pressurized tubes or uniaxial tension testing of flattened tubes with differing thermo-mechanical histories and hydrogen contents [2-8].

The internal pressure within the cladding tube during drying results in a multi-axial stress state within the cladding tube characterized by an axial stress component (minor principal stress) in addition to the tensile hoop stress (major principal stress). There is also the possibility that fuel-cladding interaction may cause an even more complex stress state on a local basis. The influence of a multi-axial stress state on hydride reorientation in cladding material has not been investigated in a systematic manner to date. In this study, the role of stress state on hydride reorientation is assessed over a range of stress states induced by specially designed Zircaloy-4 specimens that are subjected to specially designed thermo-mechanical treatments.

The Zircaloy-4 sheet material in this study was furnished by Teledyne Wah-Chang in the cold-worked stress-relieved condition with a nominal thickness of 0.67 mm, and exhibited a similar crystallographic texture and tensile properties to those of cladding tube material [9]. The experimental procedure for introducing hydrogen was developed by combining the stress-relief anneal with a hydrogen charging treatment. In this procedure, prior to hydrogen charging, the native oxide layer from the surface of the material was first removed using an acid solution, and the specimen was then coated with a 20-nm thick nickel layer to allow hydrogen ingress. A controlled amount of hydrogen-argon gas mixture (12.5% H2 and 87.5% Ar) was subsequently introduced into the chamber (initially at a pressure of less than 13.3x10-6 Pa) containing the cold-worked specimen at 500ºC. The temperature of the chamber was maintained for 2 hours to simultaneously induce stress relief and to homogenize the absorbed hydrogen through the sample thickness; the specimens were then furnace-cooled. The hydrogen concentration of each sample was determined by hot vacuum extraction. The specimens studied had hydrogen content of approx. 180 wt. ppm.

The as-hydrided microstructure consists of “in-plane” hydride platelets parallel to the sheet surface, analogous to the circumferential hydrides in Zircaloy-4 cladding tube. In order to re-orient the hydride platelets from their normal in-plane orientation into the through-thickness (“radial”) orientation, the specimens were subjected to a thermo-mechanical treatment that consisted of a 2-cycle procedure with an initial cycle consisting of heating at a rate of 5ºC up to 450°C (sufficient to dissolve 180 wt. ppm in Zircaloy-4 [10]), holding at 450ºC for 1hr, and subsequent cooling at a rate of 1˚C/min to 150°C.

Because previous studies have shown that hydride are still in solid solution at 400ºC for hydrogen content of 180wt.ppm[8, 10]), To simulate a possible vacuum drying process[11], when the temperature reached 400ºC during cooling, a constant load was applied to the sample which was maintained until a temperature of 150ºC was reached. This thermo-mechanical cycle ensured that the hydrides were completely dissolved[8, 10] at the maximum temperature for normal operating conditions[11]. The hydride microstructure was examined before and after thermo-mechanical treatments by grinding the samples with successively finer silicon carbide paper followed by etching in an acid solution consisting of 1 part of HF, 10 parts of HNO3, and 10 parts of H2O to reveal the hydrides.

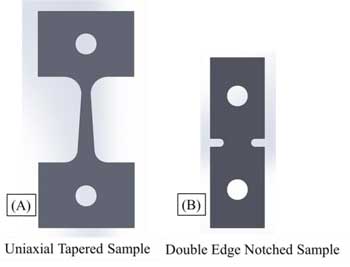

Figure 1 shows the two types of tensile specimens used in this study. Tapered uniaxial tension specimens (Fig. 1 (a)) were machined from Zircaloy-4 sheet with their stress axis oriented in the long-transverse direction of the sheet, which corresponds to the hoop direction of the cladding tube. The taper within the gauge section caused the tensile stress to vary by approximately 45% over the length (13.06 mm) of the gauge section, which had a maximum width of 3.75mm. The length to width ratio of the gauge section exceeded the four-to-one ratio recommended by ASTM for such specimens. [12]

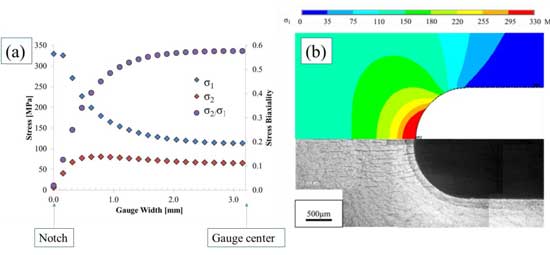

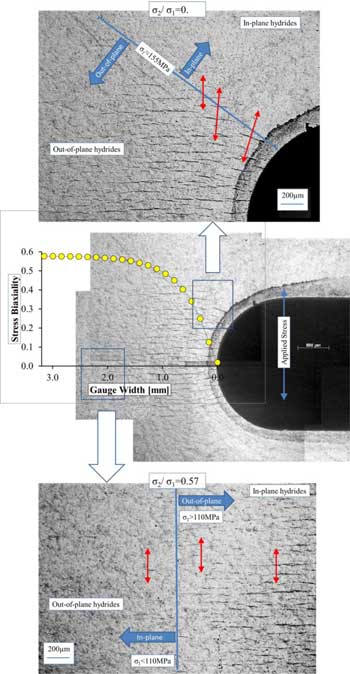

The other type of sample was the double-edge notched “Penn State” flat plane-strain specimen, which imposes a multiaxial stress state on the sample [13]; see Figure 1b. To achieve multiaxial stress state conditions within the tests specimens, Zircaloy-4 sheet with a width of 12.7 mm and length of 40 mm were machined to have a notch opening of 2 mm and a notch radius of 1 mm. This specimen configuration creates a range of multiaxial stress states that can be characterized by the stress biaxiality ratio σ2/σ1, where σ1 is the major principal stress and σ2 is the minor principal stress. The small thickness of the sheet creates a plane-stress condition such that the third principal stress σ3= 0. As shown by finite element analysis a characteristic of the double edge notch specimen is that in the elastic regime, it creates biaxial stress states that vary from σ2/σ1= 0.57 at the center of the gauge section to σ2/σ1= 0 near the notch, as seen in Figure 2. With this knowledge, the effect of stress biaxiality on the radial hydride precipitation can be studied by correlating the hydride microstructure with the local stress state at a given location. In this study, the loads applied to the specimens were in the elastic range for the locations where hydride reorientation was documented.

Figure 1. (a) Tapered uniaxial tension specimen and (b) double-edge notched specimen.

The spatial variation of stresses in the double edge notch specimen requires the use of finite element analysis as shown in Figure 2(a) to obtain the local stress values. The threshold stresses for hydride reorientation in double edge notch tension samples were obtained by matching the finite element results and the metallographic images at the same location for the onset of hydride reorientation. The major and minor principal stresses (σ1 and σ2, respectively) were calculated by both two-dimensional and three-dimensional finite element analyses at a known applied load, using the finite element software ANSYS. The Zircaloy-4 sheet material was assumed to have isotropic material properties, and the yield stress at 400ºC of Zircaloy-4 sheet (σy = 300 MPa) was determined by previous studies performed on the same material [8, 9] and confirmed by experiment in the present study. The computed stresses and the stress biaxiality ratio (σ1/σ2) were mapped onto the hydride microstructures in the metallographic images as shown in Figure 2(b). It is important to recognize that both the maximum principal stress σ1 and the stress biaxiality ratio(σ1/σ2)) vary with location within the double edge notch specimen; this feature enables the correlation of a range of stress states with hydride orientations within such a specimen.

Figure 2. (a) The principal stress and stress biaxiality distribution from notch to center of gauge section; note that σ1/σ2 = 0.57 at the center of the section and σ1/σ2= 0 near the notch. (b) An example of map of the major principal stress with reference to the hydride microstructure.

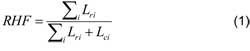

The threshold stresses were determined to be those stresses calculated at the location where the hydrides are observed to transition from circumferential to radial hydrides. For through-thickness (T-N plane) micrographs, the onset of hydride reorientation was defined as a radial hydride fraction of approximately 0.05 where the radial hydride percentage was estimated by evaluating the orientation of hydrides present in 200x200μm regions using the following relation:

where RHF is the radial hydride fraction, Lri is the length of the ith radial hydride oriented between 45-90° to the transverse direction, and Lci is the length of the ith circumferential/in-plane hydride oriented between 0-45° to the transverse direction.

The “Normal” plane (L-T) micrographs (in which the “face” of the sheet specimen is viewed) identified the locations within the double-edge notched specimen in which the onset of radial hydride formation occurred. The spatial locations of these transition regions were then coupled with the FEA-predicted stress states in these regions; the predicted stress components were based on elements consisting of nine nodes. This procedure enabled the determination of the effect of stress state on hydride reorientation over a range of stress states within each individual specimen.

Both extrinsic and intrinsic parameters affect radial hydride precipitation. Extrinsic parameters include the characteristics of the heating and cooling cycles, the applied stress, and the global stress state of the cladding material. The intrinsic parameters include grain size and orientation, crystallographic texture, degree of cold work, hydrogen content, and initial hydride microstructure[5]. This study focuses on the effect of the global or far-field stress state on hydride reorientation, and more specifically on the threshold stress. In this study, the threshold stress for hydride reorientation in tapered tensile specimens (uniaxial tension) is contrasted to that occurring within double edge notch samples (multi-axial tension).

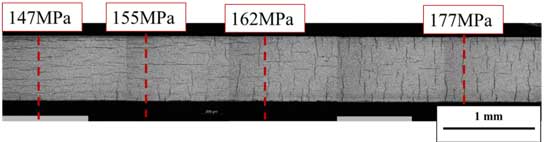

Figure 3 shows the hydride microstructure in uniaxial tension (σ2/σ1=0) for a tapered tensile specimen containing 180 wt. ppm hydrogen and subjected to the 2-cycle heating-cooling treatment described earlier. The hydrides are observed to transition from in-plane hydrides to radial hydrides at an applied tensile stress of about 155MPa. A high degree of hydride reorientation is achieved above 177MPa, whereas, the radial hydride fraction is equal to zero at stress levels below 147MPa, where only in-plane hydrides are observed in the microstructure. An analysis of this specimen and other similar samples indicates that for the Zircaloy-4 material used in this study the threshold stress to initiate radial hydride precipitation under a uniaxial tension stress state is 155 ± 10MPa.

Figure 3. The hydride microstructure of a tapered uniaxial tension sample after the 2-cycle thermo-mechanical treatment. The threshold stress for hydride reorientation is approximately 155MPa. The image is a through-thickness view of the microstructure.

The hydride reorientation behavior under multiaxial stress states (σ2/σ1>0) was examined by matching the locations of the metallographic images and finite element analysis derived from the double edge notched specimens. Figure 4 depicts both the resulting hydride microstructure after a hydride reorientation test within a double-edge notch tension sample and the stress biaxiality ratio σ2/σ1present during the test at the center plane of the sample and plotted from the center of the specimen to the notch tip. The hydride microstructure in the Figure 4 is that viewed on the “normal” plane which contains both the transverse and rolling directions of the sheet specimen. The “in-plane” hydrides in Figure 4 are oriented parallel to the plane of view, and therefore, they are not observable in the micrograph. However, the “radial” hydrides which are perpendicular to the normal plane of the sample (or parallel to the normal direction) and can be clearly seen.

By examining specimens subjected to a range of applied loads it was possible to assess the locations for the onset of hydride reorientation. As shown in Figure 4, the location within the double-edge notch specimen dictates the local stress state such that the stress biaxiality at the notch is equal to zero (uniaxial tension), but it increases rapidly with distance from the notch such that σ2/σ1=0.57 near the center of the gauge section under the elastic conditions for this analysis. We should note that at other locations near the notch (above or below the minimum width section) the state of stress is also near uniaxial tension, i.e. σ2/σ1≈0. Thus, a range of stress states can be found at various locations within the specimen gauge section. In the present study, the threshold stress for hydride reorientation was determined for a range of stress biaxiality ratios by identifying the location where the onset of radial hydrides occurred and calculating the corresponding stress state at that location for the given load.

Figure 4. (a)The radial hydride microstructure and stress biaxiality ratio (σ2/σ1) across the gauge section of a double edge notch tensile sample. At the applied stress in this test, radial hydrides are visible in the uniaxial tensile region near notch where the local value of the maximum principal stress exceeds 155MPa (a-1). At stress biaxiality ratio of 0.57, the transition from in-plane to out-of-plane hydrides occurs at maximum principal stress of 110MPa (a-2). The red arrows show the orientation of major principal stress direction at those locations.

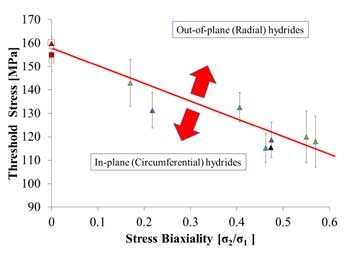

Careful analysis of various tests conducted in specimens subjected to a range of applied loads and showing data such as shown in Figure 5 revealed an effect of stress biaxiality on the threshold stress required to initiate radial hydride precipitation. Specifically for a given principal stress, while radial hydrides are observed in regions subject to biaxial tension (σ2/σ1>0), other regions of the specimen experiencing uniaxial tension (σ2/σ1≈0) show no radial hydrides. Consistent with data from uniaxial tension specimens (see Figure 3), an average threshold stress of 155 ± 10MPa is also found at the locations in double-edge notch specimens where there is a uniaxial stress state.

Figure 5 shows the threshold stress variation as a function of stress biaxiality. Three tapered uniaxial tension and five double-edge notched samples, all with approx. 180 wt. ppm. H, were used. For the tapered uniaxial samples, 3-5 measurements from through-thickness micrographs were taken at locations where in-plane to out-of-plane transition occurs. For double edge notched samples, 10 measurements were taken from through-thickness micrographs and 6-10 measurements were taken from “normal” view micrographs.

Figure 5 indicates that the threshold stress to initiate the radial hydride precipitation decreases as the stress biaxiality increases. From the 155MPa-value in uniaxial tension, the threshold stress decreases to 115 ± 7MPa for a stress biaxiality of σ2/σ1 = 0.5, which corresponds to that present in an internally pressurized tube. These results show that radial hydride precipitation is enhanced by multiaxial stress states such that radial hydrides precipitate at lower maximum principal stresses when a minor principal tensile stress is present. Such considerations should be taken into account when evaluating the likelihood of radial hydride re-precipitation during preparation for dry storage as the stress state in that case should be closer to plane-strain biaxial than uniaxial.[14]

Figure 5. The threshold stress (major principal stress) for the onset of radial hydride formation as a function of stress biaxiality. The specimens contained ≈180 wt. ppm H and were subjected to the described 2-cycle thermo-mechanical treatment described in the text. Each data point is the average of 3 to 5 measurements. Different colors indicate different tests.

Given that this research was conducted on unirradiated hydrided material, it is legitimate to ask whether the results obtained (in particular the sensitivity of the critical stress for hydride reorientation to stress state) are also valid for irradiated material. On the one hand several researchers have demonstrated that hydride reorientation occurs in irradiated material. [15,16] Daum and co-workers have indeed shown that the critical stress for hydride reorientation is the same whether irradiated or unirradiated hydrided material is tested.[17] On the other hand the mechanical properties of irradiated material have been changed because of radiation damage, the presence of irradiation induced defects can provide nucleation sites and the hydride distribution is considerably different because of the temperature gradients present under irradiation. However, because the stress state likely to be prevalent during drying operations of irradiated spent fuel is likely to be between plane strain and equibiaxial tension depending on the degree of bonding between the fuel and the cladding, it would be advisable to investigate the process of hydride reorientation under higher degrees of stress biaxiality.

The effect of the far-field stress state on the threshold stress for hydride reorientation was systematically investigated in Zircaloy-4 containing 180 wt. ppm of hydrogen and subjected to a 2-cycle thermo-mechanical treatment. The analysis of hydride microstructures in both tapered uniaxial and double-edge notch tensile specimens show that the threshold stress to initiate radial hydride precipitation decreases with increasing stress biaxiality ratio. Specifically, the threshold stress decreases from ≈155 to ≈115MPa as stress biaxiality (σ2/σ1) increases from 0 (uniaxial tension) to 0.5 (characteristic of internally pressurized cladding).

This research was funded by the Nuclear Regulatory Commission, under the supervision of Harold Scott. The research for this publication was supported by the Pennsylvania State University Materials Research Institute Nano Fabrication Network and the National Science Foundation Cooperative Agreement No. 0335765, National Nanotechnology Infrastructure Network with Cornell University. Use of the Advanced Photon Source is supported by the U.S. Department of Energy, Office of Basic Energy Sciences under Contract No. DE-AC02-06CH11357. The authors thank Jon Almer and Jun-Sang Park at APS for their help in running the experiments.

R. S. Daum, S. Majumdar, Y. Y. Liu, and M. C. Billone, Radial-hydride embrittlement of high-burnup Zircaloy-4 fuel cladding. Journal of Nuclear Science and Technology, 2006, vol. 43, pp. 1054-1067

Billone, M.C., T.A. Burtseva, and R.E. Einziger, Ductile-to-brittle transition temperature for high-burnup cladding alloys exposed to simulated drying-storage conditions. Journal of Nuclear Materials, 2013. 433(1–3): p. 431-448

Aomi, M., et al., Evaluation of Hydride Reorientation Behavior and Mechanical Properties for High-Burnup Fuel-Cladding Tubes in Interim Dry Storage. Journal of ASTM International, 2008. 5(9): p. Paper ID JAI101262.

Louthan Jr, M.R. and R.P. Marshall, Control of hydride orientation in Zircaloy. Journal of Nuclear Materials, 1963. 9(2): p. 170-184.

Kearns, J.J. and C.R. Woods, Effect of texture, grain size, and cold work on the precipitation of oriented hydrides in Zircaloy tubing and plate. Journal of Nuclear Materials, 1966. 20(3): p. 241-261.

Ells, C.E., The stress orientation of hydride in zirconium alloys. Journal of Nuclear Materials, 1970. 35: p. 306-315.

Chu, H.C., S.K. Wu, and R.C. Kuo, Hydride reorientation in Zircaloy-4 cladding. Journal of Nuclear Materials, 2008. 373(1-3): p. 319-327.

Colas, K.B., A.T. Motta, J.D. Almer, M.R. Daymond, M.Kerr,A.D Banchik, P.Vizcaino, and J.R. Santisteban, In situ study of hydride precipitation kinetics and re-orientation in Zircaloy using synchrotron radiation. Acta Materialia, 2010. 58(20): p. 6575-6583.

Raynaud, P.A., D.A. Koss, and A.T. Motta, Crack growth in the through-thickness direction of hydrided thin-wall Zircaloy sheet. Journal of Nuclear Materials, 2011. 420(1-3): p. 69-82.

McMinn, A., E.C. Darby, J.S. Schofield, Zirc. in the Nuc. Ind.: 12th Int. Symp., ASTM STP 1354, 2000, pp. 173–195

Interim Staff Guidance - 11, Rev. 3, 2003,Cladding considerations for the transportation and storage of spent fuel, U. S. Nuclear Regulatory Commission, Spent Fuel Project Office. 2003.

ASTM, 2001, Standard Methods for Tension Testing of Metallic Materials, ASTM E8-00b, Annual Book of ASTM Standards, vol. 03.01, ASTM, West Conshohocken, PA, 2001, p. 56

Link, T.M., D.A. Koss, and A.T. Motta, Failure of Zircaloy Cladding under transverse plane-strain deformation. Nuclear Engineering and Design, 1998. 186: p. 379-394.

Desquines, J., D. A., Koss, A. T., Motta, B., Cazalis, and M., Petit, The issue of stress state during mechanical tests to assess cladding performance during a reactivity-initiated accident (RIA). Journal of Nuclear Materials, 2011. 412(2): p. 250-267.

Aomi, M., Baba, T., Miyashita, T., Kamimura, K., Yasuda, T., Shinohara, Y., et al., "Evaluation of Hydride Reorientation Behavior and Mechanical Properties for High-Burnup Fuel-Cladding Tubes in Interim Dry Storage," Journal of ASTM International, vol. 5, p. Paper ID JAI101262, 2008.

Chung, H. M., R. S., Daum, J. M., Hiller, and M. C., Billone, "Characteristics of hydride precipitation and reorientation in spent-fuel cladding," Zirconium in the Nuclear Industry: Thirteenth International Symposium, ASTM STP 1423, pp. 561-582, 2002.

Daum, R. S., S., Majumdar, Y. Y., Liu, M. C., Billone, (2006). "Radial-hydride embrittlement of high-burnup Zircaloy-4 fuel cladding." Journal of Nuclear Science and Technology 43(9): 1054-1067.

http://www.euronuclear.org/e-news/e-news-49/PIME2016.htm

Every year, during the PIME (Public Materials Information Exchange) conference, a flagship event organised by the European Nuclear Society (ENS), the PIME Award for Communications Excellence is presented to the creator of what is judged to be the most effective, results-oriented communications campaign launched recently in the nuclear sector.

There is no shortage of awards being presented every day; some might say too many. But there is only one stand-out award that recognises excellence when it comes to communicating on the sensitive and specialised area that is nuclear energy - the PIME Award for Communications Excellence.

So, what is it that makes this award stand out from the crowd? What is its special added value? The answer is peer review. From a professional perspective there is nothing more satisfying than getting the recognition and praise of your fellow communicators, or knowing that your efforts have perhaps inspired them to find solutions to meet their communications challenges. It’s also about sharing with others.

A jury of nuclear communications professionals assesses all the entries and a shortlist of the best ones is drawn up. These shortlisted campaigns are then presented, showcased and “sold” to PIME delegates during the conference. The delegates, your fellow communications professionals, then cast their votes and the winner is determined. The award is presented at the end of the conference.

If you have achieved success with a recent communications campaign don’t keep it to yourself. Share it with others and send it to ENS. If it is shortlisted it will be centre stage during the 2016 PIME Conference, which is taking place in Bucharest, Romania, from 14 – 17 February 2016.

If you know of another communications campaign that is worthy of being entered for the award, but perhaps its creator is too modest, please let us know and it can be assessed too along with all the other camapigns.

You could soon be the proud winner of the 2016 PIME Award for Communications Excellence. It can also provide your organisation with the oxygen of publicity and inspire your fellow communicators around the world to achieve similar success!

Send in your campaign entry NOW and take part in the 2016 PIME Award for Communications Excellence.

MARK YOUR DIARY – Join us in Bucharest from 14 – 17 February 2016

PIME 2016 Conference Secretariat

organised in collaboration with:

http://www.euronuclear.org/e-news/e-news-49/RRFM2016.htm

The RRFM/IGORR 2016 Programme Committee is calling for both oral and poster presentations regarding

Research reactor nuclear fuel cycle - conversion to LEU fuels; fissile material supply; fresh fuel and targets: origin, qualification, fabrication; in-core fuel management and safety; fuel transportation; fuel and reactor licensing; fuel back-end management including reprocessing, spent fuel storage, corrosion and degradation; fuel cycle economics.

Low power research reactors, critical and subcritical assemblies – utilisation, research, education and training programmes, core conversion, licensing, new projects.

Utilisation of research reactors – nuclear science and technology including support for nuclear power programmes; E&T; industrial and medical applications, including radio-isotopes production and irradiation/transmutation technology; research reactor networks and coalitions; strategic and business plans.

Innovative methods in reactor physics and thermo-hydraulics – development and application of advanced computational methods and tools for core load management (operational and safety analysis, and fuel cycle physics); benchmark exercises; nuclear data improvements.

New research reactor projects - national/regional plans or construction updates of new research reactors; lessons learned from new research reactor projects; development of national infrastructures.

Research reactor operation & maintenance and ageing management, – managing reliability issues (commissioning, early operation to end of life related issues); ageing management, modernization, refurbishment, long term operation and life-time extension; maintenance management systems; human resource development and training programmes.

Research reactor safety - implementation of updated international safety standards; review of national regulatory requirements on safety and of licensing activities; design review and upgrades including associated facilities (spent fuel storage facilities); safety analysis methods and approaches; Lessons learned after Fukushima Daiichi and complementary safety assessments.

Research reactor security – implementation of updated international security recommendations; review of national security regulatory requirements; cyber security standards and facility upgrades; security management; review of emergency and contingency plans; interface security; threat assessment and design basis threat in RR security;

Decommissioning and dismantling of research reactors and waste management – strategies and concepts; decommissioning planning; economics; licensing; decontamination and measures to reduce radiation exposure; radiation and environmental protection; treatment, storage and disposal of radioactive waste; logistics and transportation; running projects; D&D lessons learned.

Mark your diaries and be a part of it! Upload your abstracts on www.rrfm2016.org before 6 November 2015.

The abstracts received will be peer reviewed under the auspices of the RRFM/IGORR 2016 Programme Committee. Authors will be notified of paper acceptance by 18 December 2016.

Conference Secretariat

C/o European Nuclear Society

56 avenue des Arts- 1000 Brussels, Belgium

Tel. +32 2 505 30 54 - Fax +32 2 502 39 02

rrfm2016@euronuclear.org

www.rrfm2016.org

http://www.euronuclear.org/e-news/e-news-49/NESTet2016.htm

NESTet is designed to facilitate an exchange of information and the sharing of best practice in nuclear education and training. It is an important networking opportunity for better co-ordination and collaboration between different stakeholders.

The conference targets directors and managers in charge of recruitment and training in companies and research centers, professors, teachers and trainers responsible for devising and delivering education and training as well as coordinators and networkers bringing together stakeholders in nuclear education and training.

Looking to bring together a broad range of experience and best practice, the NESTet Programme Committee is calling for input on the following topics:

Managing the nuclear supply chain: what are employers doing in the workplace to ensure the availability of skills and competences needed? Which methods and processes are applied to manage the internal supply chain? What are critical jobs and competences within the nuclear supply chain and how is this issue managed? What examples exist of effective/successful co-operation between industry, Universities and other stakeholders? What are Universities doing to meet the changing nature of delivery?

How to ensure that enough motivated and competent workforce is available for the nuclear sector? How to encourage skilled professionals with general engineering or project management competence to join the nuclear sector? How to retain skilled workforce? How to ensure skilled workforce in a context of a long-term-exit strategy?

A focus on excellence in project management: we are different! Are we different? What methods and processes are applied to manage key processes and/or complex projects? What are best practice examples? How do organisations build the leadership team´s capacity to successfully lead the organization and to improve performance? How to they organise leadership training? How do they enable leaders to take the right decisions? How do they bridge cultural gaps in an increasingly international industry?

Combining theoretical and practical courses for the comprehensive competence building: what is the contribution of practical courses like laboratory works, experiments carried out on nuclear facilities and exercises carried out on simulators in competence building?

What are the tools recently developed for nuclear education and training? At different levels and with different pedagogical objectives, a broad range of new techniques and tools have been developed for nuclear education and training. These techniques and tools include Massive Open Online Courses (MOOCs), distant learning courses, reactor experiments broadcasted through internet, new software applications and simulators. NESTet 2016 is looking for examples of these new techniques and tools, their application and their feedback.

Generation Y meets Generation III: How to adapt communication, teaching and coaching to the needs and mind-sets of the next generation? How to encourage the choice of STEM subjects in secondary schools and Universities? How to attract young professionals to the sector? How to manage the pedagogical challenges of clashing ages in the nuclear workforce?

Discover the ‘maze’ of networks: What are existing initiatives? Are they beneficial for partners, Universities and/or industry? How can we optimise networking? How can we effectively network with Eastern Partnership Countries to make these networks beneficial for all? How can networks collaborate?

The NESTet Programme Committee welcomes both oral and poster submissions and encourages particularly the presentation of best practice examples.

If you wish to share knowledge and best practice in nuclear education and training in science, engineering and technology, please submit your abstract by 27 November 2015 through the NESTet Abstract Submission System.

Important dates:

Deadline for abstract submission: 27 November 2015

Notification of authors: 30 January 2016

Deadline for full paper submission: 22 April 2016

Deadline for submission of PowerPoint presentations: 6 May 2016

Conference: 22 – 26 May 2016

NESTet 2016 Conference Secretariat:

Tel: + 32 2 505 30 54

Fax: +32 2 502 3902

e-mail: nestet2016@euronuclear.org

www.nestet2016.org

http://www.euronuclear.org/e-news/e-news-49/ENC2016.htm

ENC 2016 provides a platform for the nuclear science community to share their experience and to learn about the latest developments going on in nuclear research and their practical applications. It will furthermore exploit synergy among scientists, industry representatives, policy-makers and citizens on wider societal issues that impact upon how the nuclear science community carries out its work.

ENS and the ENC 2016 Programme Committee are now calling for abstracts in the following areas:

Nuclear science applications for industry and society

Silicon doping; neutron activation analysis including PGAA and delayed neutron detection; isotopes production and supply; water desalination; heat cogeneration; sterilisation; hydrogen generation; non-destructive testing including neutron radiography and tomography; nuclear in space; instrumentation; geochronology, gem stone coloration;...

Life science applications

Radiation protection; low-dose research; environmental studies; diagnostics and therapeutic applications; development of new radiopharmaceuticals; instrumentation; ...

Advanced reactor technologies

Innovative technologies for Generation III+ reactors; Generation IV reactors; small and modular reactors; innovative reactor concepts, including the Thorium cycle; research reactor and testing facilities; fusion reactors; nuclear data; space propulsion reactors; naval civil reactors; floating nuclear plants; …

Current reactor technologies and new build